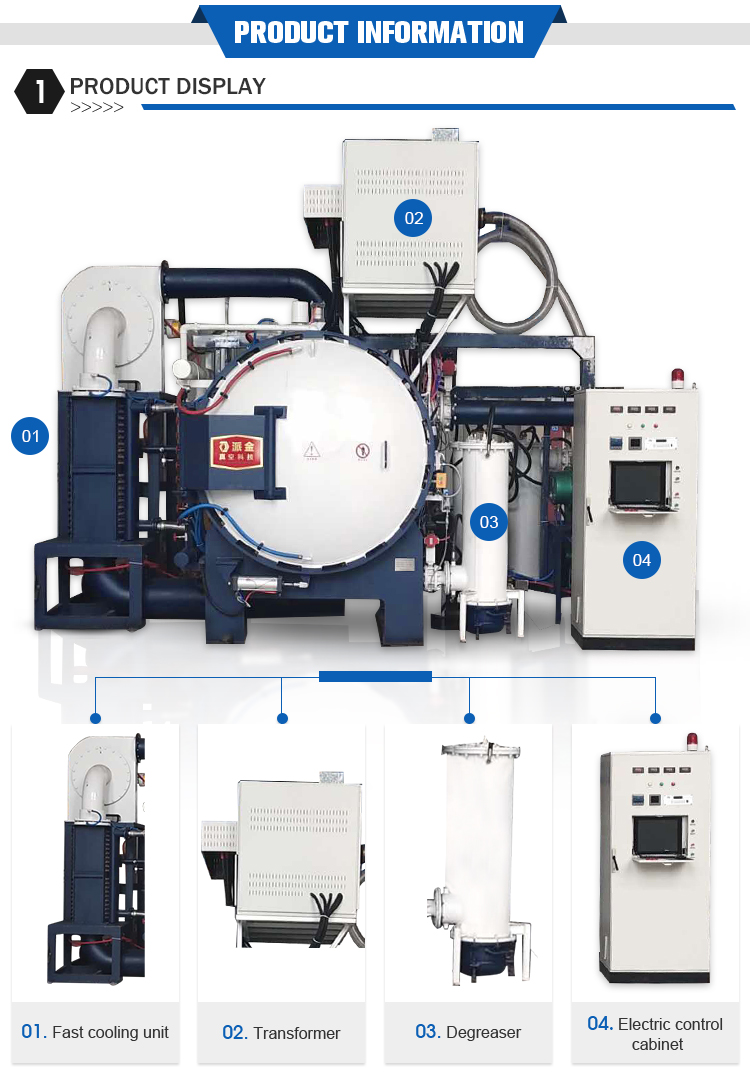

Vacuum Debinding uye Sintering furnace (MIM Furnace, Powder metallurgy furnace)

Hunhu

1. Graphite insulation sikirini / simbi sikirini zvokusarudza, kudziyisa chinhu 360 dhigirii surround radiation kudziyisa, yakavimbika insulation dhizaini.

2. Kufanana kwekushisa kwepamusoro uye kushanda kwekushisa

3. Vacuum partial pressure / multi-area temperature control function.

4. Midziyo yemagetsi yakakwana, kuchengetedzwa kwakakwana uye abnormal alarm system.

5. Yakarurama nzira yekutonga kuti uwane inowirirana chikamu chehutano uye kudzivirira kusvibiswa kwezvikamu uye nzvimbo dzinopisa.

6. Nebhokisi rakavharwa degreasing uye vacuum condenser kuderedza kusvibiswa kwekamuri yekupisa uye chikwata.

7.Kudzivirira kusvibiswa kune zvikamu muchoto. Iyo square degreasing bhokisi inoshandiswa kubata nehuwandu hukuru hwekuumba additives.

8. Iine mabasa e-flexible vacuum extraction, vacuum sintering, micro-positive pressure sintering nezvimwe zvakadaro.

9. Iyo yazvino yekupisa yekupisa chimiro uye zvinhu zvinoshandiswa, kumanikidza kupikisa kwakasimba, uye kuponesa kwesimba kuri pachena.

10.Iyo ine mabasa ekuwedzera kupisa uye overpressure alarm, mechanical automatic pressure protection, automaticoverpressure rubatsiro kudzivirira, chiito interlock uye zvichingodaro, yakakwirira michina kuchengeteka.

11.Remote operation, kure kure kutadza kuongororwa uye kure software upgrade mabasa, nezvimwewo.

Standard modhi yakatarwa uye parameters

| Model | PJSJ-gr-30-1600 | PJSJ-gr-60-1600 | PJSJ-gr-100-1600 | PJSJ-gr-200-1600 | PJSJ-gr-450-1600 |

| Inoshanda inopisa nzvimbo LWH (mm) | 200*200*300 | 300*300* 600 | 300*300* 900 | 400*400* 1200 | 500*500* 1800 |

| Huremu hwekutakura (kg) | 100 | 200 | 400 | 600 | 10000 |

| Kupisa simba (kw) | 65 | 80 | 150 | 200 | 450 |

| Kunyanya tembiricha(℃) | 1600 | ||||

| Tembiricha kutonga kurongeka (℃) | ±1 | ||||

| Kufanana kwekushisa kwechoto (℃) | ±3 | ||||

| Shanda vacuum degree (Pa) | 4.0 * E -1 | ||||

| Kupomba mitengo (kusvika 5 pa) | ≤10 min | ||||

| Kukwidziridza mwero (Pa/H) | ≤ 0.5 | ||||

| Debinding rate | >97.5% | ||||

| Debinding nzira | N2 mukumanikidza kwakashata, H2 mumhepo | ||||

| Input gasi | N2,H2,A | ||||

| Kutonhodza nzira | inert gasi kutonhora | ||||

| Sintering nzira | Vacuum sintering, partial pressure sintering, pressure sintering | ||||

| Chimiro chevira | Horizontal, single chamber | ||||

| Nzira yekuvhura gonhi revira | Hinge type | ||||

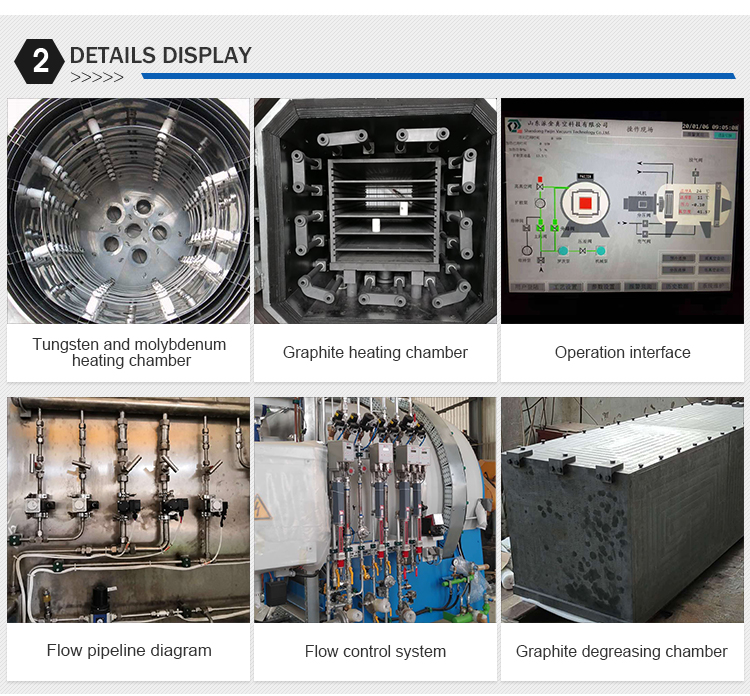

| Kupisa zvinhu | Graphit kudziyisa zvinhu | ||||

| Heating chamber | Kuumbwa kwechimiro cheGraphit yakaoma yakanzwa uye yakapfava inonzwa | ||||

| Thermocouple | C Type | ||||

| PLC & zvinhu zvemagetsi | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Pombi yevacuum | Mechanical pombi uye pombi yemidzi | ||||

| Customized sarudzo siyana | |||||

| Maximum tembiricha | 1300-2800 ℃ | ||||

| Maximum tembiricha degree | 6.7 * E -3 Pa | ||||

| Chimiro chevira | Yakachinjika, Yakatwasuka, Kamuri imwechete | ||||

| Door kuvhura nzira | Hinge type, Kusimudza mhando, Flat type | ||||

| Kupisa zvinhu | Graphit kudziyisa zvinhu, Mo kudziyisa zvinhu | ||||

| Heating chamber | Yakagadzirwa graphit yakanzwa, Yese simbi inoratidza skrini | ||||

| Vacuum pombi | Mechanical pombi uye midzi pombi; Mechanical, Midzi uye diffusion pombi | ||||

| PLC & zvinhu zvemagetsi | Siemens; Omron; Mitsubishi; Siemens | ||||

| Temperature controller | EUROTHERM;S HIMADEN | ||||