Kupisa kwesimbi isina tsvina

1. Brazeability

Dambudziko rekutanga musimbi isina tsvina nderekuti iyo oxide firimu iri pamusoro inokanganisa zvakanyanya kunyorova uye kupararira kwe solder. Masimbi akasiyana-siyana asina tsvina ane huwandu hwakati wandei hweCr, uye mamwe anewo Ni, Ti, Mn, Mo, Nb uye zvimwe zvinhu, izvo zvinogona kugadzira akasiyana oxides kana kunyange composite oxides pamusoro. Pakati pavo, maokisi Cr2O3 uye TiO2 yeCr uye Ti akanyatsogadzikana uye akaoma kubvisa. Paunenge uchivhenekera mumhepo, mhepo inoshanda inofanira kushandiswa kuvabvisa; Kana uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchingedza mumhepo, iyo oxide firimu inogona kuderedzwa chete mukuchena kwemhepo ine yakaderera dova uye tembiricha yakakwira; Mune vacuum brazing, zvinodikanwa kuve neyakakwana vacuum uye tembiricha yakakwana kuti uwane yakanaka brazing mhedzisiro.

Imwe dambudziko resimbi isina simbi yesimbi nderekuti kupisa kwekushisa kune kukanganisa kwakakomba pane chimiro chesimbi yepasi. Iyo yekudziya yekudziya tembiricha yeaustenitic simbi isina tsvina haifanire kunge yakakwira kupfuura 1150 ℃, zvikasadaro zviyo zvinokura zvakanyanya; Kana austenitic Stainless simbi isina yakagadzikana chinhu Ti kana Nb uye ine yakakwira kabhoni yemukati, brazing mukati mekunzwa tembiricha (500 ~ 850 ℃) inofanira kudzivirirwa. Kudzivirira kudzivirira kwecorrosion kubva mukudzikira nekuda kwekunaya kwechromium carbide. Kusarudzwa kwekushisa kwekupisa kwemartensitic simbi isina tsvina kwakanyanyisa. Imwe ndeyekufananidza tembiricha yekudziya neyakadzima tembiricha, kuitira kuti ubatanidze iyo brazing process pamwe nekupisa kurapwa maitiro; Imwe yacho ndeyekuti kupisa kwebrazing kunofanirwa kunge kwakadzikira pane tembiricha yekudzivirira kudzivirira base simbi kubva pakupfava panguva yekubhuroka. Iyo brazing tembiricha yekusarudza misimboti yekunaya inoomesa simbi isina tsvina yakangofanana neyemartensitic simbi isina tsvina, ndiko kuti, tembiricha yebrazing inofanira kuenderana neyakagadziriswa yekupisa system kuti iwane yakanakisa michina zvinhu.

Pamusoro pematambudziko makuru maviri ari pamusoro apa, pane katsika kekupwanya kushushikana kana uchikwenya austenitic simbi isina tsvina, kunyanya kana uchibhuroka nemhangura zinc filler simbi. Kuti udzivise kuputika kwekushushikana, iyo workpiece ichave yekunetseka kuderedzwa yakanyungudutswa isati yabhomba, uye workpiece ichave yakaenzana kupisa panguva yebrazing.

2. Kupisa zvinhu

(1) Zvinoenderana nezvinodiwa zvekushandiswa kwesimbi isina tsvina, iyo inowanzo shandiswa brazing filler simbi yesimbi isina tsvina inosanganisira Tin Lead brazing filler simbi, sirivheri based brazing filler simbi, mhangura based brazing filler simbi, manganese based brazing filler simbi, nickel based brazing filler simbi uye yakakosha simbi brazing filler simbi.

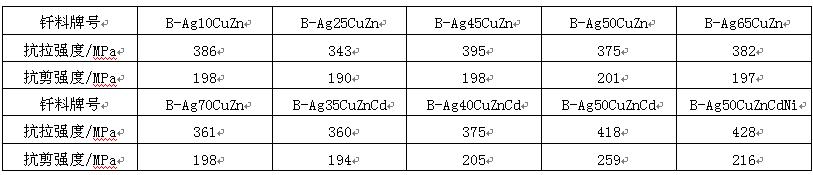

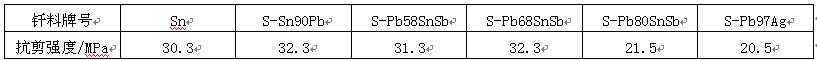

Tin lead solder inonyanya kushandiswa kugadzira simbi isina tsvina, uye inokodzera kuve nemhando yepamusoro yetin. Iyo yakakwirira iyo tini yemukati ye solder, zviri nani kunyorova kwayo pasimbi isina tsvina. Simba rekugera re1Cr18Ni9Ti majoini esimbi asina tsvina akashongedzwa neakawanda akajairika tin lead solders akanyorwa muTebhu 3. Pamusana pesimba rakaderera remajoini, anongoshandiswa kubhuroka zvikamu zvine madiki ekutakura.

Tafura 3 kugera simba re1Cr18Ni9Ti simbi isina tsvina yakabatana yakashongedzwa netin lead solder

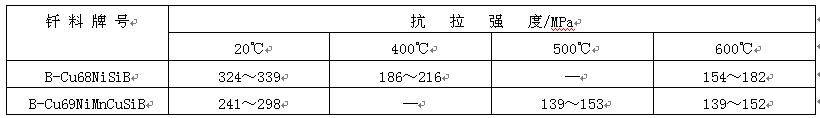

Silver based filler metals ndiwo anonyanya kushandiswa simbi dzekuzadza kubhuroka simbi isina tsvina. Pakati pazvo, sirivheri yemhangura zinc uye sirivheri yemhangura zinc cadmium filler simbi inonyanya kushandiswa nekuti tembiricha yebrazing haina mhedzisiro pane zvivakwa zvesimbi yepasi. Simba re ICr18Ni9Ti Stainless simbi majoini akashongedzwa neakawanda akajairika esirivha based solders akanyorwa muTebhura 4. Majoini esimbi asina tsvina akashongedzwa nesirivha-based solders haawanzo shandiswa munhau dzinoparadza zvakanyanya, uye tembiricha yekushanda yemajoini kazhinji haipfuure 300 ℃. Kana uchibhurocha simbi isina nickel, kuitira kudzivirira kuparara kwejoints yakanyungudutswa munzvimbo ine hunyoro, brazing simbi ine nickel yakawanda ichashandiswa, senge b-ag50cuzncdni. Kana uchigadzira martensitic simbi isina tsvina, kuitira kudzivirira kupfava kwesimbi yepasi, brazing filler simbi ine brazing tembiricha isingapfuuri 650 ℃ ichashandiswa, senge b-ag40cuzncd. Kana uchisunga simbi isina tsvina mumhepo inodzivirira, kuitira kubvisa iyo oxide firimu pamusoro, lithium ine self brazing flux inogona kushandiswa, yakadai se b-ag92culi uye b-ag72culi. Kana uchigadzira simbi isina tsvina muvacuum, kuitira kuti simbi yekuzadza irambe iine kunyorova kwakanaka kana isina zvinhu zvakaita seZn neCD zviri nyore kubuda, simbi yekuzadza sirivha ine zvinhu zvakaita seMn, Ni uye RD inogona kusarudzwa.

Tafura 4 simba re ICr18Ni9Ti simbi isina tsvina yakabatana yakashongedzwa nesirivha yakavakirwa filler simbi.

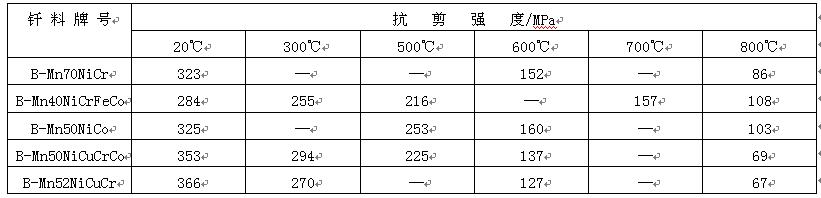

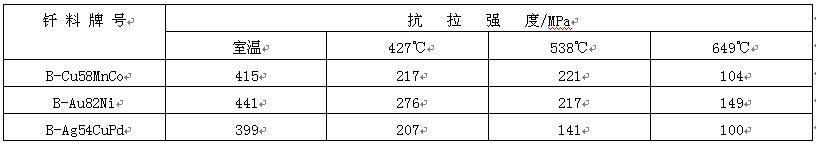

Mhangura yakavakirwa brazing filler masimbi anoshandiswa kubhurosa simbi dzakasiyana anonyanya kuchena mhangura, mhangura nickel uye mhangura manganese cobalt brazing filler simbi. Yakachena mhangura brazing filler simbi inonyanya kushandiswa kubhuroka pasi pekudzivirira gasi kana vacuum. Kushanda tembiricha yesimbi isina simbi yakabatana haipfuure 400 ℃, asi iyo joint ine kushomeka kweoxidation resistance. Mhangura nickel brazing filler simbi inonyanya kushandiswa kupisa murazvo uye induction brazing. Simba rebrazed 1Cr18Ni9Ti simbi yesimbi isina tsvina inoratidzwa muTebhu 5. Inogona kuonekwa kuti mubatanidzwa une simba rakafanana nesimbi yepasi, uye kutonhora kwekushanda kwakakwirira. Cu Mn co brazing filler simbi inonyanya kushandiswa kugadzira martensitic simbi isina tsvina mumhepo inodzivirira. Iyo yakabatana simba uye tembiricha yekushanda inofananidzwa neiyo yakashongedzwa negoridhe based filler simbi. Semuyenzaniso, 1Cr13 Stainless simbi yakabatana yakashongedzwa neb-cu58mnco solder ine mashandiro akafanana nesimbi isina tsvina yakasanganiswa yakashongedzwa neb-au82ni solder (ona Tafura 6), asi mutengo wekugadzira wakadzikiswa zvakanyanya.

Tafura 5 shear simba re1Cr18Ni9Ti simbi isina tsvina yakabatana yakashongedzwa neyakapisa tembiricha yemhangura base filler simbi.

Tafura 6 shear simba re 1Cr13 simbi isina tsvina yakasanganiswa

Manganese based brazing filler metals anonyanya kushandiswa gasi kudzivirirwa brazing, uye kuchena kwegasi kunodiwa kuve kwakakwira. Kuti udzivise kukura kwezviyo kwesimbi yepasi, simbi inoenderana neyakagadzika yekuzadza ine brazing tembiricha yakaderera pane 1150 ℃ inofanira kusarudzwa. Inogutsa brazing effect inogona kuwanikwa yesimbi isina tsvina majoini akashongedzwa ne manganese based solder, sezvakaratidzwa muTebhu 7. Kupisa kwekushanda kwejoint kunogona kusvika 600 ℃.

Tafura 7 shear simba re lcr18ni9fi simbi isina tsvina yakabatana yakashongedzwa ne manganese based filler simbi.

Kana simbi isina tsvina yakashongedzwa nenickel base yekuzadza simbi, iyo joint ine yakanaka yepamusoro tembiricha kuita. Iyi simbi yekuzadza inowanzo shandiswa gasi yakadzivirirwa brazing kana vacuum brazing. Kuti ukunde dambudziko rekuti mamwe brittle makomisheni anogadzirwa mujoini yakashongedzwa panguva yekuumbwa kwemajoini, izvo zvinoderedza zvakanyanya kusimba uye mapurasitiki ejoint, gaka rekubatana rinofanira kudzikiswa kuti ive nechokwadi chekuti zvinhu zviri nyore kuumba brittle phase mune solder zvakapararira zvizere mu base simbi. Kuti udzivise kuitika kwebhesi yesimbi yezviyo kukura nekuda kwenguva yakareba yekubata panguva yekupisa tembiricha, maitiro ekugadzirisa kwenguva pfupi kubata uye kupararira kurapwa pakadzika tembiricha (zvichienzaniswa nekushisa kwebrazing) mushure mekugadzira inogona kutorwa.

Noble simbi brazing filler simbi dzinoshandiswa kubhuroka simbi isina tsvina kunyanya dzinosanganisira goridhe-based filler metals uye palladium ine filler simbi, ayo anonyanya kufanana ari b-au82ni, b-ag54cupd uye b-au82ni, ane zvakanaka kunyorova. Iyo brazed Stainless simbi yakabatana ine yakakwirira tembiricha simba uye oxidation kuramba, uye yakanyanya tembiricha yekushanda inogona kusvika 800 ℃. B-ag54cupd ine hunhu hwakafanana neb-au82ni uye mutengo wayo wakaderera, saka inowanzo kutsiva b-au82ni.

(2) Kumusoro kwesimbi isina tsvina mumhepo inoyerera uye muchoto mumhepo ine okisidhi yakadai seCr2O3 uye TiO2, inogona kubviswa chete nekushandisa flux ine basa rakasimba. Kana simbi isina tsvina yakashongedzwa netin lead solder, flux yakakodzera phosphoric acid aqueous solution kana zinc oxide hydrochloric acid solution. Iyo nguva yekuita ye phosphoric acid aqueous solution ipfupi, saka nzira yebrazing yekukurumidza kupisa inofanira kutorwa. Fb102, fb103 kana fb104 fluxes inogona kushandiswa kugadzira simbi isina tsvina ine sirivheri based filler simbi. Kana uchibhurocha simbi isina tsvina ine mhangura yakavakirwa simbi yekuzadza, fb105 flux inoshandiswa nekuda kwekushisa kwakanyanya.

Kana uchipisa simbi isina tsvina muchoto, vacuum mhepo kana inodzivirira mamiriro akaita sehydrogen, argon uye decomposition ammonia inowanzoshandiswa. Munguva yevacuum brazing, iyo vacuum pressure ichave yakaderera pane 10-2Pa. Paunenge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchi mhepo tembiricha, chidimbu chidiki chegasi brazing flux, senge boron trifluoride, inogona kuwedzerwa kumhepo.

2. Brazing teknolojia

Simbi isina tsvina inofanira kucheneswa zvakanyanya musati mabvongodza kubvisa chero girizi nemafuta firimu. Zviri nani kubhuroka pakarepo mushure mekuchenesa.

Stainless simbi brazing inogona kutora murazvo, induction uye choto chepakati kupisa nzira. Icho choto chekuputira muchoto chinofanira kunge chine yakanaka tembiricha yekudzora system (kutsauka kwekushisa kwebrazing kunodiwa kuve ± 6 ℃) uye inogona kutonhodzwa nekukurumidza. Kana haidrojeni ichishandiswa segasi rekudzivirira kubhuroka, zvinodiwa zvehydrogen zvinoenderana nekupisa kwekupisa uye kuumbwa kwesimbi yepasi, ndiko kuti, kuderera kwekushisa kwekupisa, kunowedzera simbi yepasi ine stabilizer, uye kuderera kwedova rehydrogen rinodiwa. Semuenzaniso, kune martensitic Stainless steels akadai se1Cr13 uye cr17ni2t, kana ichipisa pa1000 ℃, dova rehydrogen rinodiwa kuve rakaderera pane -40 ℃; Kune 18-8 chromium nickel simbi isina stabilizer, dova rehydrogen richadzikira pane 25 ℃ panguva yekubhuroka pa1150 ℃; Nekudaro, kune 1Cr18Ni9Ti Stainless simbi ine titanium stabilizer, iyo hydrogen dovi poindi inofanira kunge yakaderera pane -40 ℃ kana ichibhuroka pa1150 ℃. Paunenge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchingedzo, kuchena kweargon kunodiwa kuve kwakakwirira. Kana mhangura kana nickel yakaputirwa pamusoro pesimbi isina tsvina, chinodiwa chekuchena kwekudzivirira gasi chinogona kuderedzwa. Kuti uone kubviswa kweiyo oxide firimu pamusoro pesimbi isina tsvina, BF3 gasi flux inogonawo kuwedzerwa, uye lithium kana boron ine self flux solder inogona kushandiswa zvakare. Kana vacuum brazing simbi isina tsvina, izvo zvinodikanwa zvevacuum degree zvinoenderana nekupisa kwekupisa. Nekuwedzera kwekushisa kwebrazing, vacuum inodiwa inogona kuderedzwa.

Iyo huru maitiro esimbi isina tsvina mushure mekubhuroka ndeyekuchenesa yakasara flux uye yakasara kuyerera inhibitor, uye kuita post brazing kupisa kurapwa kana zvichidikanwa. Zvichienderana nekuyerera uye nzira yebrazing inoshandiswa, yakasara flux inogona kugezwa nemvura, kucheneswa nemichina kana kucheneswa nemakemikari. Kana abrasive inoshandiswa kuchenesa yakasara flux kana oxide firimu munzvimbo inopisa padyo nejoint, jecha kana zvimwe zvisiri zvesimbi zvinyoro zvinyoro zvichashandiswa. Zvikamu zvakagadzirwa nemartensitic Stainless simbi uye kunaya kwemvura kuomesa simbi isina tsvina inoda kurapwa kwekupisa zvinoenderana nezvinodiwa zvakakosha zvezvinhu mushure mekubhuroka. Simbi isina majoini akashongedzwa neNi Cr B uye Ni Cr Si filler masimbi anowanzo kurapwa nekupisa kupisa kurapwa mushure mebrazing kudzikisa zvinodikanwa zvebrazing gap uye kugadzirisa microstructure uye zvivakwa zvemajoini.

Nguva yekutumira: Jun-13-2022