1. Kupisa zvinhu

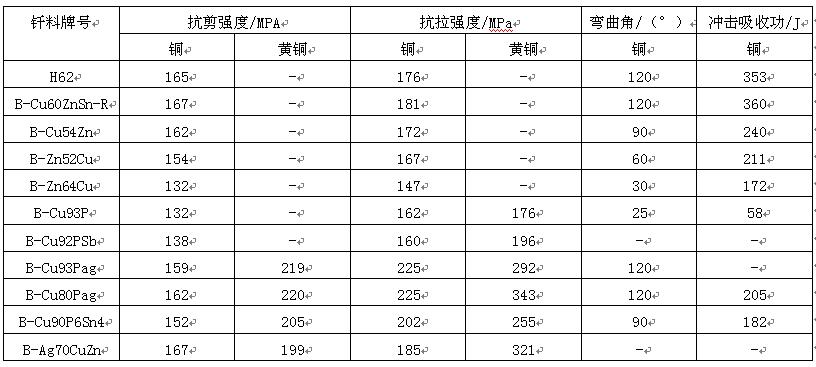

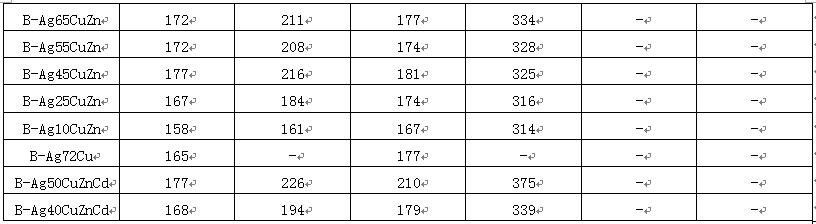

(1) Kusimba kwekubatanidza kwemasoja akati wandei anowanzo shandiswa kwemhangura nendarira brazing inoratidzwa patafura 10.

Tafura 10 simba remhangura nemhangura brazed joints

Paunenge uchigadzira mhangura ine tin lead solder, isina corrosive brazing flux yakadai serosin alcohol solution kana inoshanda rosin uye zncl2 + nh4cl aqueous solution inogona kusarudzwa.Iyo yekupedzisira inogona zvakare kushandiswa kugadzira ndarira, ndarira uye beryllium bronze.Paunenge uchigadzira ndarira yealuminium, aluminium bronze uye silicon ndarira, iyo brazing flux inogona kuve zinc chloride hydrochloric acid mhinduro.Kana uchigadzira manganese chena mhangura, iyo jekiseni mumiriri inogona kuve phosphoric acid mhinduro.Zinc chloride aqueous solution inogona kushandiswa se flux kana uchibhuroka nelead based filler simbi, uye fs205 flux inogona kushandiswa pakubhuroka necadmium based filler simbi.

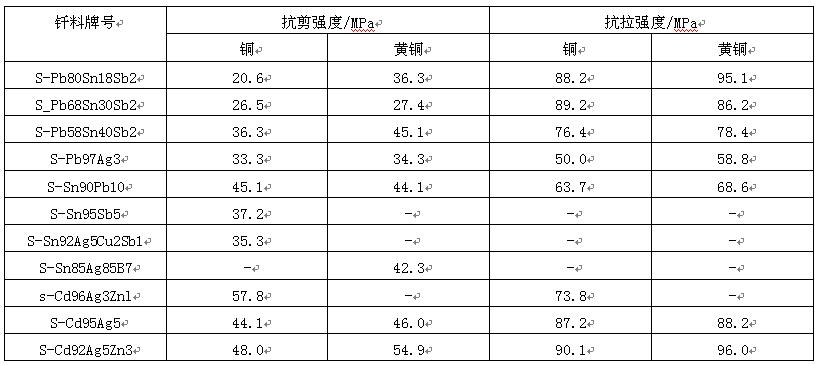

(2) Pakushongedza mhangura ine brazing filler simbi uye fluxes, sirivheri based filler simbi uye mhangura phosphorus filler simbi inogona kushandiswa.Silver based solder ndiyo inonyanya kushandiswa yakaoma solder nekuda kwekunyungudika kwayo ine mwero, yakanaka processability, yakanaka mechanical properties, magetsi uye thermal conductivity.Kune iyo workpiece inoda yakakwirira conductivity, b-ag70cuzn solder ine yakakwira sirivheri yemukati ichasarudzwa.Yevacuum brazing kana brazing mune inodzivirira mamiriro evira, b-ag50cu, b-ag60cusn uye zvimwe zvinongedzo zvesimbi zvisina zvinhu zvinoputika zvichasarudzwa.Brazing filler metals ine yakaderera sirivheri yemukati yakachipa, ine yakanyanya kupisa tembiricha uye kushomeka kwakashata kwemajoini akasungwa.Iwo anonyanya kushandiswa kubhuroka mhangura nemhangura alloys ane zvakaderera zvinodiwa.Mhangura phosphorus uye mhangura phosphorus sirivheri brazing filler simbi inogona chete kushandiswa kubhuroka kwemhangura uye ayo alloys emhangura.Pakati pazvo, b-cu93p ine mvura yakanaka uye inoshandiswa kubrazing zvikamu zvisingaenderane nekukanganisa mutoro muElectromechanical, chiridzwa uye maindasitiri ekugadzira.Mukana unonyatsokodzera ndeye 0.003 ~ 0.005mm.Mhangura phosphorus sirivha brazing filler metals (senge b-cu70pag) ine kusimba kuri nani uye conductivity pane mhangura phosphorus brazing filler simbi.Iwo anonyanya kushandiswa kumagetsi majoini ane yakakwirira conductivity zvinodiwa.Tafura 11 inoratidza majoini ezvivakwa zvakati wandei zvakajairwa brazing zvinhu zvinoshandiswa kubheza mhangura nendarira.

Tafura 11 zvimiro zvemhangura nendarira brazed majoini

Nguva yekutumira: Jun-13-2022