1. Brazeability

Izvo zvakaoma kumisa ceramic uye ceramic, ceramic uye simbi zvikamu.Yakawanda ye solder inoumba bhora pamusoro peceramic surface, ine zvishoma kana kusatota.Iyo brazing filler simbi inogona kunyorovesa ceramics iri nyore kugadzira akasiyana brittle makomisheni (senge carbides, silicides uye ternary kana multivariate makomisheni) pajoinhi interface panguva yebrazing.Kuvapo kwezvisanganiswa izvi kunokanganisa maitiro emagetsi ejoini.Pamusoro pezvo, nekuda kwekusiyana kukuru kwemafuta ekuwedzera coefficients pakati peceramic, simbi uye solder, pachava nekusarira kunetseka mumubatanidzwa mushure mekunge tembiricha yekudziya yatonhodzwa kusvika kune tembiricha yekamuri, izvo zvinogona kukonzera kuputika kwemajoini.

Iko kunyorova kweiyo solder pamusoro peceramic surface inogona kuvandudzwa nekuwedzera inoshanda simbi zvinhu kune yakajairika solder;Kupisa kwakadzika uye kupfupika kwekanguva kubhuroka kunogona kuderedza mhedzisiro yeinterface reaction;Kupisa kwekushushikana kwejoinhi kunogona kuderedzwa nekugadzira fomu yakakodzera yekubatana uye kushandisa imwe chete kana yakawanda-layer metal seyepakati.

2. Solder

Ceramic nesimbi zvinowanzobatanidzwa muvhavha yevira kana hydrogen uye argon furnace.Pamusoro pezvakajairwa hunhu, brazing filler simbi yevacuum yemagetsi zvishandiso inofanirawo kuve nezvimwe zvakakosha zvinodiwa.Semuenzaniso, iyo solder haifanirwe kunge iine zvinhu zvinoburitsa yakakwira mhute kumanikidza, kuitira kuti isakonzeresa dielectric leakage uye cathode chepfu yemidziyo.Zvinowanzotaurwa kuti kana mudziyo uchishanda, mhute yekumanikidza ye solder haifanire kudarika 10-3pa, uye yakakwira mhute yekumanikidza kusvibiswa kurimo haifaniri kudarika 0.002% ~ 0.005%;Iyo w (o) ye solder haifanire kudarika 0.001%, kuitira kudzivirira mhute yemvura inogadzirwa panguva yekugadzika muhydrogen, iyo inogona kukonzera kudonha kwesimbi yakanyungudutswa solder;Mukuwedzera, solder inofanira kuva yakachena uye isina maokisi epamusoro.

Kana kubhuroka mushure meceramic metallization, mhangura, base, sirivheri mhangura, goridhe mhangura uye mamwe alloy brazing filler simbi anogona kushandiswa.

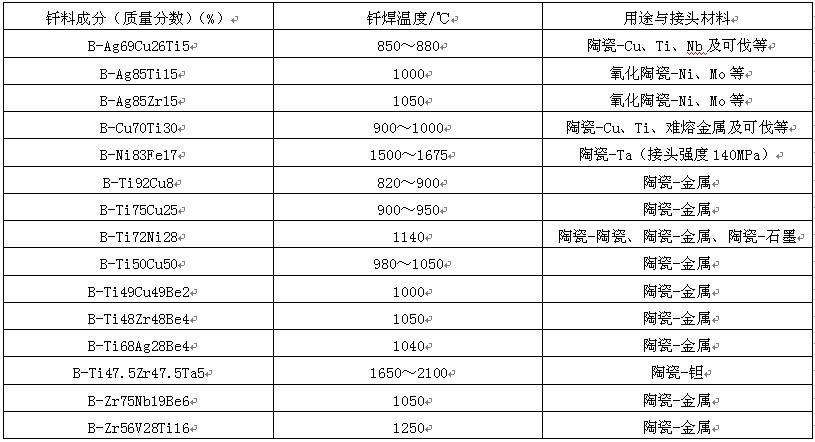

Kune yakananga brazing yekeramics nesimbi, brazing filler simbi ine inoshanda zvinhu Ti uye Zr ichasarudzwa.Iwo mabhinari mafirita masimbi akanyanya Ti Cu uye Ti Ni, anogona kushandiswa pa1100 ℃.Pakati peiyo ternary solder, Ag Cu Ti (W) (TI) ndiyo inonyanya kushandiswa solder, iyo inogona kushandiswa kunanga kubhuroka kweakasiyana marara nesimbi.Iyo ternary filler simbi inogona kushandiswa nefoiri, hupfu kana Ag Cu eutectic filler simbi ine Ti poda.B-ti49be2 brazing filler simbi ine zvakafanana corrosion resistance kune Stainless simbi uye yakaderera mhute pressure.Inogona kuve yakasarudzika yakasarudzwa mune vacuum yekuisa chisimbiso majoini ane oxidation uye leakage kuramba.Mune ti-v-cr solder, tembiricha yekunyunguduka ndiyo yakaderera (1620 ℃) apo w (V) iri 30%, uye kuwedzera kweCr kunogona kunyatso kudzikisa tembiricha yekunyungudika.B-ti47.5ta5 solder isina Cr yakashandiswa kunangana brazing yealumina uye magnesium oxide, uye kubatana kwayo kunogona kushanda pane ambient tembiricha ye1000 ℃.Tafura 14 inoratidza iyo inoshanda flux yekubatanidza yakananga pakati peceramic nesimbi.

Tafura 14 inoshanda brazing filler masimbi eceramic uye simbi brazing

2. Brazing teknolojia

Iyo pre metallized ceramics inogona kuve yakashongedzwa mune yakakwirira-kuchena inert gasi, hydrogen kana vacuum nharaunda.Vacuum brazing inowanzo shandiswa kune yakananga brazing yemakeramiki pasina simbi.

(1) Universal brazing process iyo yepasirese brazing process yeceramic nesimbi inogona kukamurwa kuita manomwe maitiro: kuchenesa pamusoro, paste coating, ceramic surface metallization, nickel plating, brazing uye post weld inspection.

Chinangwa chekuchenesa pamusoro ndechekubvisa tsvina yemafuta, dikita uye oxide firimu pamusoro pesimbi yepasi.Zvikamu zvesimbi uye solder zvichave zvakasvibiswa kutanga, ipapo iyo oxide firimu ichabviswa neasidhi kana alkali washing, yakashambidzwa nemvura inoyerera uye yakaomeswa.Zvikamu zvine zvakakwirira zvinodikanwa zvinopisa kupisa muvira revacuum kana hydrogen vira (ion bombardment nzira inogonawo kushandiswa) patembiricha yakakodzera uye nguva yekuchenesa pamusoro pezvikamu.Zvikamu zvakacheneswa hazvifanirwe kusangana nezvinhu zvine mafuta kana maoko asina maoko.Ivo vanozoiswa pakarepo muchikamu chinotevera kana muomesa.Havazopinzwa mumhepo kwenguva yakareba.Ceramic parts zvinofanira kucheneswa neacetone uye ultrasonic, kusukwa nemvura inoyerera, uye pakupedzisira kubikwa kaviri nemvura yakasvibiswa kwe15min nguva imwe neimwe.

Paste coating inzira yakakosha yeceramic metallization.Panguva yekuputira, inoiswa kune iyo ceramic pamusoro kuti isimbiswe nebhurashi kana namatidza coating muchina.Ukobvu hwekuputira kazhinji 30 ~ 60mm.Iyo paste inowanzo gadzirwa kubva yakachena simbi poda (dzimwe nguva yakakodzera simbi oxide inowedzerwa) ine particle size inosvika 1 ~ 5um uye organic adhesive.

Zvikamu zvakanamirwa zveceramic zvinotumirwa kuchoto chehydrogen uye chakanyungudutswa nehydrogen yakanyorova kana yakatsemuka ammonia pa1300 ~ 1500 ℃ ye30 ~ 60min.Kune zvikamu zveceramic zvakaputirwa nemahydrides, zvinopiswa kusvika ku900 ℃ kuti zviparadze mahydrides uye kuita nesimbi yakachena kana titanium (kana zirconium) inosara pamusoro peceramic kuti iwane simbi yekuputira pamusoro peceramic surface.

Kune Mo Mn metallized layer, kuti inyorove ne solder, nickel layer ye 1.4 ~ 5um inofanira kuiswa nemagetsi kana kuputirwa nehupfu hwe nickel.Kana tembiricha yebrazing yakadzikira kupfuura 1000 ℃, iyo nickel layer inoda pre sintered muchoto chehydrogen.Iyo sintering tembiricha uye nguva ndeye 1000 ℃ /15 ~ 20min.

Maceramic akacheneswa zvikamu zvesimbi, izvo zvinozounganidzwa pamwechete nesimbi isina tsvina kana graphite uye ceramic molds.Solder ichaiswa pamajoini, uye workpiece ichachengetwa yakachena mukati mekushanda, uye haifaniri kubatwa nemaoko asina maoko.

Kupisa kuchaitwa mu argon, hydrogen kana vacuum choto.Iyo tembiricha yekudziya inotsamira pane brazing filler simbi.Kuti udzivise kuputika kwezvikamu zveceramic, mwero wekutonhora haufanirwe kukurumidza.Uye zvakare, brazing inogona zvakare kushandisa imwe kudzvanywa (inenge 0.49 ~ 0.98mpa).

Pamusoro pekutariswa kwemhando yepamusoro, iyo brazed weldments ichavewo pasi pekuvhunduka kwekupisa uye mekiniki yekuongorora zvivakwa.Zvikamu zvekuisa chisimbiso zvevacuum zvishandiso zvinofanirwawo kuve pasi pekuyedzwa kwekuvuza zvinoenderana nemirairo yakakodzera.

(2) Direct brazing paunenge uchigadzira zvakananga (inoshanda simbi nzira), tanga wachenesa pamusoro peceramic uye simbi weldments, wozozvibatanidza.Kuti udzivise kutsemuka kunokonzerwa neakasiyana-siyana ekuwedzera kwemafuta coefficients echikamu chemidziyo, iyo buffer layer (imwe kana akawanda akaturikidzana emarata esimbi) anogona kutenderedzwa pakati peweldments.Iyo brazing yekuzadza simbi inosungirirwa pakati pemawelds maviri kana kuiswa panzvimbo iyo gaka rinozadzwa nesimbi yekuzadza simbi kusvika pazvinobvira, uye ipapo brazing ichaitwa seyakajairwa vacuum brazing.

Kana Ag Cu Ti solder ichishandiswa kunanga brazing, vacuum brazing nzira ichagamuchirwa.Kana iyo vacuum degree muchoto inosvika 2.7 × Kutanga kupisa pa10-3pa, uye tembiricha inogona kusimuka nekukurumidza panguva ino;Kana tembiricha iri pedyo nekunyunguduka kwe solder, tembiricha inofanira kusimudzwa zvishoma nezvishoma kuita kuti tembiricha yezvikamu zvese zve weldment ifanane;Kana solder yanyungudutswa, tembiricha ichasimudzwa nekukurumidza kusvika pakupisa kwebrazing, uye nguva yekubata ichave 3 ~ 5min;Munguva yekutonhodzwa, ichatonhodzwa zvishoma nezvishoma isati yasvika 700 ℃, uye inogona kutonhodzwa zvega nechoto mushure me700 ℃.

Kana Ti Cu inoshanda solder yakanyatso bhurazwa, chimiro chesolder chinogona kunge chiri Cu foil pamwe neTi poda kana Cu zvikamu pamwe neTi foil, kana iyo ceramic pamusoro inogona kuputirwa neTi poda pamwe neCu foil.Pamberi pekugadzikiswa, simbi dzese dzinofanira kubviswa ne vacuum.Iyo tembiricha yekubvisa mweya weokisijeni isina mhangura ichave 750 ~ 800 ℃, uye Ti, Nb, Ta, nezvimwewo ichabviswa pa900 ℃ kwe15min.Panguva ino, dhigirii yevacuum haifaniri kunge iri pasi pe6.7 × 10-3Pa. Panguva yekugadzira, unganidza zvikamu kuti zvisungirwe mukugadzirisa, zvipise muchoto chekutsvaira kusvika 900 ~ 1120 ℃, uye nguva yekubata i2 ~. 5min.Munguva yese yekushongedza, iyo vacuum degree haifanire kunge iri pasi pe6.7 × 10-3Pa.

Iyo brazing process yeTi Ni nzira yakafanana neyeTi Cu nzira, uye tembiricha yekudziya i900 ± 10 ℃.

(3) Oxide brazing nzira oxide brazing nzira inzira yekuona yakavimbika kubatanidza nekushandisa girazi chikamu chinoumbwa nekunyunguduka kweoxyde solder kuti ipinde mumakeramiki uye kunyorovesa simbi pamusoro.Inogona kubatanidza zvidhori nemakeramiki uye zvidhori zvine simbi.Oxide brazing filler metals inonyanya kuumbwa neAl2O3, Cao, Bao uye MgO.Nekuwedzera B2O3, Y2O3 uye ta2o3, brazing filler simbi dzine akasiyana mapoinzi ekunyungudika uye mutsara wekuwedzera coefficients inogona kuwanikwa.Pamusoro pezvo, fluoride brazing filler metals neCaF2 uye NaF sezvinhu zvikuru zvinogona kushandiswa kubatanidza ceramics nesimbi kuwana majoini ane simba rakawanda uye kupisa kwakanyanya.

Nguva yekutumira: Jun-13-2022