vacuum gasi rinodzima choto Yakatsetseka ine kamuri imwe chete

Chii chinonzi vacuum gasi kudzima

Vacuum gasi quenching ndiyo nzira yekudziya iyo workpiece pasi pevacuum, uye wozoitonhodza nekukurumidza mumhepo inotonhorera ine high pressure uye high flow rate, kuitira kuti uvandudze kuoma kwepamusoro pe workpiece.

Kuenzaniswa neyakajairwa gasi kudzimwa, kudzima oiri uye kugeza munyu kudzima, vacuum yakakwirira-kudzvanywa gasi kudzima kune zvakanakira zviri pachena: kunaka kwepamusoro, hapana oxidation uye hapana carburization; Good quenching kufanana uye diki workpiece deformation; Yakanaka controllability yekudzima simba uye inodzoreka kutonhora mwero; Kubudirira kwepamusoro, kuchengetedza basa rekuchenesa mushure mekudzima; Hapana kusvibiswa kwezvakatipoteredza.

Pane zvinhu zvakawanda zvakakodzera vacuum high-pressure gas quenching, kunyanya kusanganisira: high-speed simbi (zvakadai sekucheka maturusi, simbi molds, inofa, geji, mabhengi ejet injini), simbi yemidziyo (wachi zvikamu, zvigadziriso, zvitsigiro), simbi inofa, inotakura simbi, nezvimwe.

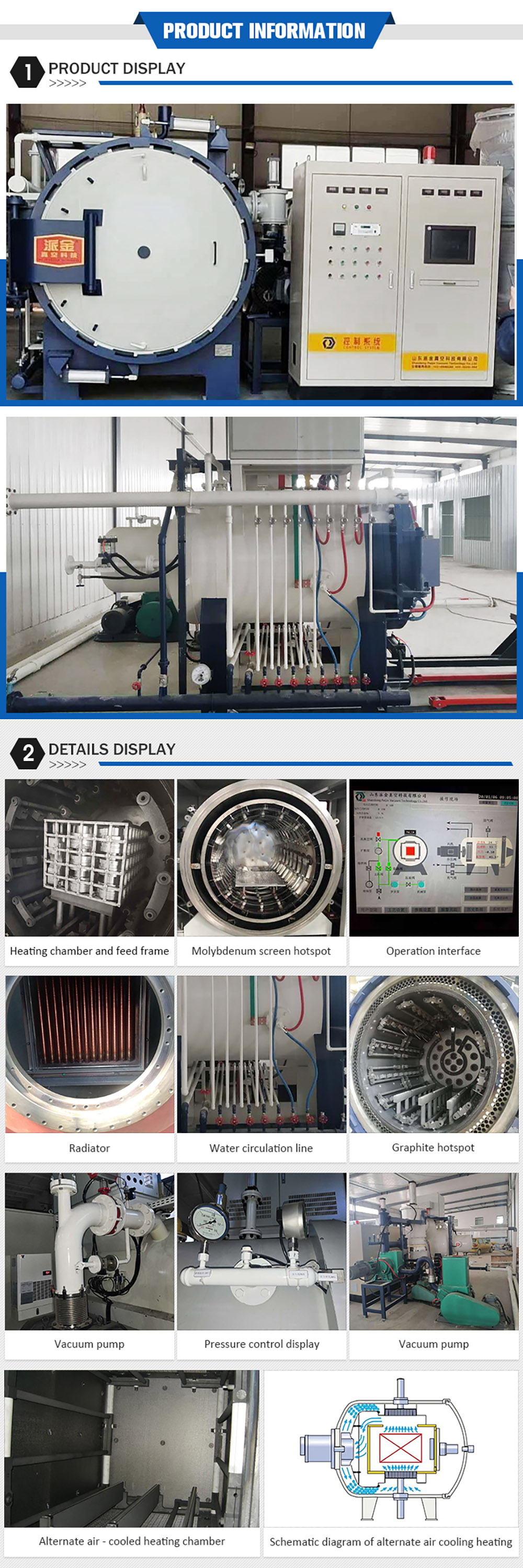

Paijin Vacuum gasi rekudzima choto chevira inosanganisirwa nechoto muviri, imba yekudziya, inopisa yekusanganisa fan, vacuum system, gasi yekuzadza system, vacuum partial pressure system, yemagetsi control system, mvura kutonhora system, gasi kudzima system, pneumatic system, otomatiki yekupa magetsi trolley.

Application

Paijin Vacuum gasi rinodzima chotoinokodzera kudzima kurapwa kwezvinhu zvakaita sesimbi inofa, simbi inomhanya-mhanya, simbi isina tsvina, nezvimwe; mhinduro kurapwa kwezvinhu zvakadai sesimbi isina tsvina, titanium uye titanium alloy; annealing kurapwa uye kudziya kurapwa kweakasiyana magineti zvinhu; uye inogona kushandiswa vacuum brazing uye vacuum sintering.

Hunhu

1. High cooling speed:nekushandisa yakakwirira kunyatsoshanda square heat exchanger, kutonhora kwayo kunowedzerwa ne80%.

2. Kutonhodza kwakanaka kufanana:Mhepo dzemhepo dzakafanana uye dzakadzika dzakamiswa dzakatenderedza imba yekudziya.

3.Kuchengetedza Simba Kwakakwirira:Mhepo dzayo dzemhepo dzinovhara otomatiki mukupisa, inoita kuti simba rayo riite 40% zvishoma.

4. Kufanana kwekushisa kurinani:zvinhu zvayo zvinodziya zvakagadzirirwa zvakaenzana kumativi ose ekamuri yekudziya.

5. Inokodzera kwakasiyana siyana maitiro:Imba yekudziya yekamuri yekudziya inogadzirwa neyakaomeswa yakaoma insulating layer kana simbi insulating sikirini, yakakodzera kune akasiyana nharaunda.

6. Yakangwara uye iri nyore yekugadzira hurongwa, yakagadzikana uye yakavimbika mechanical chiito, otomatiki, semi-otomatiki kana manually anotyisa uye kuratidza zvikanganiso.

7. Frequency conversion control gasi quenching fan, optional convection air heat, optional 9 points tembiricha ongororo, partial pressure quenching uye isothermal quenching.

8. Neyese AI control system uye imwe yekuwedzera manual operating system.

Standard modhi yakatarwa uye parameters

| Standard modhi yakatarwa uye parameters | |||||

| Model | PJ-Q557 | PJ-Q669 | PJ-Q7711 | PJ-Q8812 | PJ-Q9916 |

| Inoshanda Kupisa Zone LWH (mm) | 500*500*700 | 600*600*900 | 700*700 * 1100 | 800*800 * 1200 | 900*900 * 1600 |

| Kurema Kwemutoro(kg) | 300 | 500 | 800 | 1200 | 2000 |

| Maximum Temperature(℃) | 1350 | ||||

| Tembiricha kutonga kurongeka (℃) | ±1 | ||||

| Kufanana kwekushisa kwechoto (℃) | ±5 | ||||

| Maximum Vacuum Degree(Pa) | 4.0 * E -1 | ||||

| Kukwidziridza mwero (Pa/H) | ≤ 0.5 | ||||

| Gasi kudzima kumanikidza (Bar) | 10 | ||||

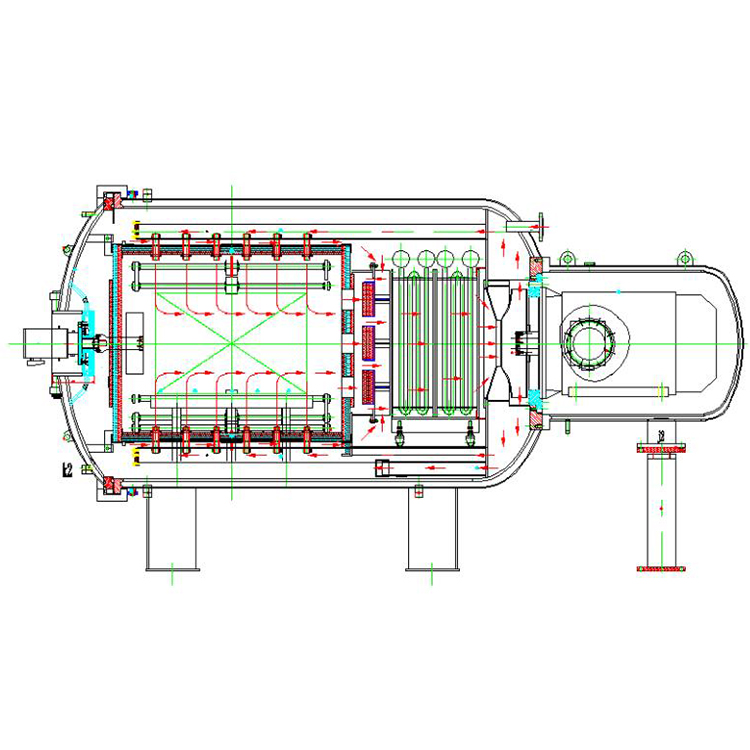

| Chimiro chevira | Horizontal, single chamber | ||||

| Nzira yekuvhura gonhi revira | Hinge type | ||||

| Kupisa zvinhu | Graphit kudziyisa zvinhu | ||||

| Heating chamber | Kuumbwa kwechimiro cheGraphit yakaoma yakanzwa uye yakapfava inonzwa | ||||

| Gasi quenching kuyerera mhando | Vertical alternating flow | ||||

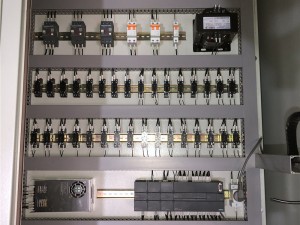

| PLC & Magetsi zvinhu | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Pombi yevacuum | Mechanical pombi uye pombi yemidzi | ||||

| Customized sarudzo siyana | |||||

| Maximum tembiricha | 600-2800 ℃ | ||||

| Maximum tembiricha degree | 6.7 * E -3 Pa | ||||

| Gasi quenching pressure | 6-20 Bar | ||||

| Chimiro chevira | Horizontal, Vertical, single chamber kana multi chamber | ||||

| Door kuvhura nzira | Hinge mhando, Kusimudza mhando, Flat mhando | ||||

| Kupisa zvinhu | Graphit kudziyisa zvinhu, Mo kudziyisa zvinhu | ||||

| Heating chamber | Yakagadzirwa Graphite yakanzwa, Yese simbi inoratidza skrini | ||||

| Gasi quenching kuyerera mhando | Horizontal alternating gasi kuyerera; Vertical alternating gasi kuyerera | ||||

| Vacuum pombi | Mechanical pombi uye midzi pombi; Mechanical, midzi uye diffusion pombi | ||||

| PLC & Magetsi zvinhu | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

Kudzora kwehutano

Hunhu ndiwo mweya wezvigadzirwa, ndiyo yakakosha poindi sarudza fekitori's ramangwana.Paijin inotora hutano sezvinhu zvinonyanya kukosha mubasa redu rezuva nezuva.Kuti tive nechokwadi chehutano hwakanaka hwezvigadzirwa zvedu, takateerera zvakanyanya pazvikamu zvitatu.

1.Chinonyanya kukosha: Munhu. Munhu ndiye chinhu chakakosha pabasa rese. Tine makosi akazara ekudzidzira mushandi wese mutsva, uye isu tine rating system yekuyera mushandi wese kusvika padanho (junior, wepakati, wepamusoro), vashandi vakasiyana vanogadzwa kumabasa akasiyana nemuhoro wakasiyana. Mune ino rating system, iyo's kwete chete hunyanzvi, asiwo chiyero mumutoro uye kukanganisa mwero, simba rekutonga etc. Nenzira iyi, vashandi mufekitari yedu vanoda kuita zvakanakisisa mubasa rake.Uye anonyatsotevera mitemo yehutano hwehutano.

2. Zvishandiso zvakanakisa uye zvikamu: Isu tinongotenga zvinhu zvakanakisa pamusika, tinoziva kuti inochengetedza 1 dhora muzvinhu inodhura madhora zana pakupedzisira. Izvo zvikamu zvakakosha semagetsi emagetsi uye pombi zvese zvigadzirwa zvemhando seSiemens, Omron,Eurotherm, Schneider etc. Kune zvimwe zvikamu zvakagadzirwa muChina, tinosarudza fekitori yakanakisa muindasitiri uye takasaina chigadzirwa chemhando yeguranntee chibvumirano navo, kuti ive nechokwadi chekuti chikamu chese chatinoshandisa muchoto ndicho chemhando yepamusoro zvigadzirwa.

3. Yakasimba Quality Management: Tine 8 yemhando yekutarisa mapoinzi mumatanho ekugadzira choto, Kuongorora mune yega yega cheki cheki inotakurwa nevashandi ve2 uye 1 maneja wefekitori ndiye ane mhosva. Mune aya macheki mapoinzi, zvinhu uye zvikamu, uye ese maficha echoto anotariswa kaviri kuti ave nechokwadi chemhando yayo. Pakupedzisira, choto chisati chabuda mufekitari, chinofanira kuongororwa kwekupedzisira nekuedza kurapwa kwekupisa.