Tsanangudzo uye chinangwa chekudzima

Simbi inopisa kusvika kune tembiricha iri pamusoro peiyo yakakosha point Ac3 (hypoeutectoid simbi) kana Ac1 (hypereutectoid simbi), inochengetwa kwenguva yakati kuti iite zvizere kana zvishoma austenitized, uye yobva yatonhodzwa nekumhanya kwakakura kupfuura yakakosha yekudzima kumhanya. Iyo yekupisa yekurapa maitiro inoshandura supercooled austenite kuita martensite kana yakaderera bainite inonzi quenching.

Chinangwa chekudzima ndechekushandura iyo supercooled austenite kuita martensite kana bainite kuti iwane martensite kana yakaderera bainite chimiro, icho chinozosanganiswa nekudziya pane dzakasiyana tembiricha kuvandudza zvakanyanya simba, kuoma, uye kuramba kwesimbi. Kupfeka, simba rekuneta uye kuoma, nezvimwewo, kusangana nezvinodiwa zvakasiyana zvekushandisa zveakasiyana makinika zvikamu uye maturusi. Kudzima kunogona zvakare kushandiswa kusangana nechakakosha chemuviri uye chemakemikari zvimiro zvemamwe masimbi akakosha senge ferromagnetism uye corrosion resistance.

Kana zvikamu zvesimbi zvatonhodzwa musvikiro rekudzima nekuchinja kwechimiro chemuviri, maitiro ekutonhora anowanzo kupatsanurwa mumatanho matatu anotevera: mhute yefirimu nhanho, nhanho yekubiira, uye nhanho yekutenderera.

Kuoma kwesimbi

Kuoma uye kuomeswa zviratidzo zviviri zvekushanda zvinoratidzira kugona kwesimbi kudzima. Iwo zvakare hwaro hwakakosha hwekusarudzwa kwezvinhu uye kushandiswa.

1. Mafungiro ekuoma uye kuoma

Kuomarara ndiko kugona kwesimbi kuti iwane kuomarara kwepamusoro kwainokwanisa kuwana kana yadzimwa uye kuomeswa pasi pemamiriro akanaka. Chinhu chikuru chinotarisa kuoma kwesimbi ndeye carbon content yesimbi. Kuti zvive zvakanyatsojeka, iyo kabhoni yemukati yakanyungudika mu austenite panguva yekudzima uye kupisa. Iyo yakakwirira iyo kabhoni yemukati, iyo yakakwirira kuoma kwesimbi. . Izvo zvinosanganiswa zvinhu musimbi zvine zvishoma zvinokanganisa kuomarara, asi zvine zvazvinoita pakuoma kwesimbi.

Kuomarara kunoreva maitiro anoona kuomarara kudzika uye kuomarara kugovera kwesimbi pasi pemamiriro akatarwa. Ndiko, kugona kuwana kudzika kweiyo yakaomeswa layer kana simbi yadzimwa. Icho chinhu chakasikwa chesimbi. Kuomarara kunoratidza kusununguka kunoita austenite kuita martensite kana simbi yadzimwa. Iyo inonyanya kuenderana nekugadzikana kweiyo supercooled austenite yesimbi, kana kune yakakosha kudzima kutonhora kutonhora kwesimbi.

Inofanirawo kutaurwa kuti kuoma kwesimbi kunofanira kusiyaniswa kubva kune hunobudirira kuoma kudzika kwezvikamu zvesimbi pasi pemamiriro chaiwo ekudzima. Kuoma kwesimbi inzvimbo yekuzvarwa yesimbi pachayo. Zvinongobva pane zvayo zvemukati zvinhu uye hazvina chokuita nekunze zvinhu. Iyo inobudirira kuomeswa kwakadzika kwesimbi kwete kungoenderana nekuoma kwesimbi, asiwo kunoenderana nezvinhu zvinoshandiswa. Iyo ine hukama nekunze zvinhu senge inotonhorera yepakati uye saizi yebasa. Semuenzaniso, pasi pemamiriro akafanana e austenitizing, kuoma kwesimbi imwe chete kwakafanana, asi kusimba kunobudirira kwekudzika kwekudzima kwemvura kwakakura kudarika kwekudzima kwemafuta, uye zvikamu zviduku zviduku pane kudzima mafuta. Iyo inobudirira kuomesa kudzika kwezvikamu zvakakura zvakakura. Izvi hazvigone kutaurwa kuti kudzima kwemvura kune kuomarara kwepamusoro pane kudzima mafuta. Hazvigoni kutaurwa kuti zvikamu zviduku zvine kuoma kwakakwirira kudarika zvikamu zvikuru. Zvinogona kuoneka kuti kuongorora kuoma kwesimbi, pesvedzero yezvinhu zvekunze senge chimiro chebasa, saizi, svikiro inotonhorera, nezvimwe zvinofanirwa kubviswa.

Mukuwedzera, sezvo kuomeswa uye kuomeswa ari maviri akasiyana pfungwa, simbi ine yakakwirira kuoma pashure quenching hazvireve ane yakakwirira kuomarara; uye simbi ine kuoma kwakaderera inogonawo kuva nepamusoro kuoma.

2. Zvinhu zvinokanganisa kuoma

Kuoma kwesimbi kunoenderana nekugadzikana kwe austenite. Chero chinhu chinogona kuvandudza kugadzikana kwe supercooled austenite, shandura iyo C curve kurudyi, uye nekudaro kuderedza yakakosha kutonhora mwero inogona kuvandudza kuoma kwesimbi yakakwira. Kugadzikana kwe austenite kunonyanya kuenderana nemakemikari ayo, saizi yezviyo uye kuumbwa kwakafanana, izvo zvinoenderana nekemikari yesimbi uye yekupisa mamiriro.

3.Measurement nzira yekuoma

Kune nzira dzakawanda dzekuyera kuomarara kwesimbi, iyo inonyanya kushandiswa ndiyo yakakosha nzira yekuyera dhayamita uye yekupedzisira-kuoma bvunzo nzira.

(1)Critical dhayamita kuyerwa nzira

Mushure mekunge simbi yadzimwa mune imwe svikiro, iyo yakakura dhayamita kana iyo core inowana martensite yese kana 50% martensite chimiro inonzi yakakosha dhayamita, inomiririrwa naDc. Iyo yakakosha dhayamita yekuyera nzira ndeyekuita mutsara wetsvimbo yakatenderedza ine madhayamita akasiyana, uye mushure mekudzima, kuyera kuomarara kweU curve yakagoverwa pamwe nedhayamita pane yega yega chikamu chikamu, uye kuwana tsvimbo ine semi-martensite chimiro pakati. Iyo dhayamita yetsvimbo yakatenderedza Ndiyo dhayamita yakakosha. Iyo yakakura iyo dhayamita yakakosha, iyo yakakwirira kuoma kwesimbi.

(2) Kugumisa quenching bvunzo nzira

Iyo yekupedzisira-yekudzima bvunzo nzira inoshandisa yakajairwa saizi yekupedzisira-yakadzimwa specimen (Ф25mm×100mm). Mushure me austenitization, mvura inopfapfaidzwa kune imwe magumo emuenzaniso pamidziyo yakakosha kuti itonhodze. Mushure mekutonhora, kuoma kunoyerwa pamwe chete neaxis direction - kubva kumagumo emvura-yakanyorova. Yedza nzira ye daro rehukama curve. Iyo yekupedzisira-kuomesa bvunzo nzira ndiyo imwe yenzira dzekuona kuoma kwesimbi. Zvakanakira zviri nyore kushanda uye yakafara application siyana.

4.Kudzima kushushikana, deformation uye kuputika

(1) Kushushikana kwemukati kweiyo workpiece panguva yekudzima

Kana iyo workpiece inokurumidza kutonhora mukati mekudzima svikiro, sezvo workpiece ine imwe saizi uye thermal conductivity coefficient iriwo imwe kukosha, imwe tembiricha gradient ichaitika pamwe nechikamu chemukati cheworkpiece panguva yekutonhora. Tembiricha yepasi yakadzikira, tembiricha yepakati yakakwira, uye tembiricha yepamusoro nepakati zvakakwirira. Pane kusiyana kwekushisa. Munguva yekutonhora kweiyo workpiece, kunewo maitiro maviri emuviri: imwe ndeyekupisa kwekuwedzera, sezvo tembiricha inodonha, kureba kwemutsara we workpiece kuchaderera; imwe ndiyo shanduko ye austenite kune martensite apo tembiricha inodonha kusvika kune martensite shanduko yenzvimbo. , izvo zvichawedzera vhoriyamu chaiyo. Nekuda kwekusiyana kwekushisa panguva yekutonhora, huwandu hwekuwedzera kwekupisa huchave hwakasiyana pazvikamu zvakasiyana pamwe nechikamu chemuchinjiko weworkpiece, uye kushushikana kwemukati kunogadzirwa munzvimbo dzakasiyana dzeworkpiece. Nekuda kwekuvapo kwekusiyana kwetembiricha mukati meiyo workpiece, panogonawo kunge paine zvikamu uko tembiricha inodonha nekukurumidza kupfuura nzvimbo inoitika martensite. Shanduko, vhoriyamu inowedzera, uye zvikamu zvine tembiricha yakakwira zvichiri kukwira kupfuura poindi uye zvichiri muaustenite state. Izvi zvikamu zvakasiyana zvinounzawo kushushikana kwemukati nekuda kwekusiyana kwekuchinja kwevhoriyamu chaiyo. Nokudaro, marudzi maviri ekushushikana kwemukati anogona kugadzirwa panguva yekudzima uye kutonhora: imwe ndeyekupisa kwekushisa; imwe yacho kushushikana kwematishu.

Zvinoenderana nekuvapo kwenguva hunhu hwekushushikana kwemukati, inogona zvakare kukamurwa kuita nekukurumidza kushushikana uye kusara kunetseka. Kushushikana kwemukati kunogadzirwa neworkpiece pane imwe nguva panguva yekutonhora kunonzi instantaneous stress; mushure mekunge workpiece yatonhodzwa, kushushikana kunosara mukati me workpiece kunonzi residual stress.

Thermal stress inoreva kushushikana kunokonzerwa nekusaenderana kwekuwedzera kwekushisa (kana kutonhora kutonhora) nekuda kwekusiyana kwekushisa munzvimbo dzakasiyana dzebasa kana ichidziya (kana kutonhora).

Iye zvino tora silinda yakasimba semuenzaniso wekuenzanisira kuumbwa uye kuchinja mitemo yekushungurudzika kwemukati panguva yekutonhora kwayo. Chete axial stress inokurukurwa pano. Pakutanga kwekutonhora, nokuti nzvimbo yacho inotonhora nokukurumidza, kutonhora kwakadzika, uye kunoderera zvakanyanya, apo musimboti wakanyoroveswa, kutonhora kwakakwirira, uye shrinkage iduku. Nekuda kweizvozvo, iyo yepamusoro uye yemukati inodzorwa, zvichikonzera kusagadzikana kwepamusoro pepamusoro, nepo musimboti uri pasi pekumanikidzwa. stress. Sezvo kutonhora kuchienderera mberi, musiyano wekushisa pakati pemukati nekunze unowedzera, uye kushushikana kwemukati kunowedzerawo maererano. Kana kushushikana kunowedzera kudarika simba regoho pane iyi tembiricha, deformation yepurasitiki inoitika. Sezvo ukobvu hwemoyo hwakakwirira kudarika hwepamusoro, mwoyo unogara uchibatana neaxially kutanga. Somugumisiro wekugadzirwa kwepurasitiki, kushushikana kwemukati hakuchawedzeri. Mushure mekutonhora kune imwe nguva yenguva, kuderera kwekushisa kwepamusoro kunononoka zvishoma nezvishoma, uye shrinkage yayo ichadererawo zvishoma nezvishoma. Panguva ino, musimboti uchiri kudzikira, saka kushushikana kwekushushikana kuri pamusoro uye kudzvanya kushushikana kuri pakati kuchaderera zvishoma nezvishoma kusvika vapera. Zvisinei, apo kutonhora kunoramba kuchienderera mberi, hunyoro hwepamusoro hunova hushoma uye hushoma, uye huwandu hwekuderera hunova hushoma uye hushoma, kana kutomira kuderera. Sezvo tembiricha yepakati ichiri yakakwira, icharamba ichidzika, uye pakupedzisira compressive kusagadzikana ichaumbwa pamusoro peiyo workpiece, nepo musimboti uchange uine kushushikana kwekunetseka. Nekudaro, sezvo tembiricha yakadzikira, deformation yepurasitiki haisi nyore kuitika, saka kushushikana uku kunowedzera sekutonhora kunoenderera. Iyo inoramba ichiwedzera uye pakupedzisira inoramba iri mukati meiyo workpiece sekusara kunetseka.

Zvinogona kuonekwa kuti kushushikana kwekushisa panguva yekutonhora kunotanga kunokonzera kuti denga repamusoro ritambanudzwe uye musimboti uomerwe, uye iyo yakasara yakasara kushushikana inzvimbo yepamusoro inofanira kumanikidzwa uye musimboti utambanudzwe.

Kupfupisa, kushushikana kwekupisa kunogadzirwa panguva yekudzima kutonhora kunokonzerwa nemuchinjiko-chikamu chetembiricha musiyano panguva yekutonhora. Iyo yakakura kutonhora kweyero uye yakakura muchinjiko-sectional tembiricha mutsauko, iyo huru yekupisa yekushushikana inogadzirwa. Pasi pemamiriro akafanana ekutonhora epakati, iyo inokwirisa tembiricha yekudziya yeworkpiece, yakakura saizi, iyo diki yekupisa conductivity yesimbi, yakakura kusiyana kwetembiricha mukati meworkpiece, uye nekunyanya kushushikana kwekupisa. Kana iyo workpiece yakatonhodzwa zvisina kuenzana pakupisa kwepamusoro, ichave yakakanganiswa uye yakaremara. Kana iko pakarepo kushushikana kwekushushikana kunogadzirwa panguva yekutonhora kweiyo workpiece yakakura kupfuura kusimba kwesimba rechinhu, kudzima mitswe ichaitika.

Phase shanduko yekushushikana inoreva kushushikana kunokonzerwa neyakasiyana nguva yekushandurwa kwechikamu munzvimbo dzakasiyana dzebasa panguva yekupisa kurapwa, inozivikanwawo setishu kusagadzikana.

Munguva yekudzima uye nekukasira kutonhora, kana iyo yekumusoro layer yatonhodzwa kusvika kuMs point, shanduko yemartensitic inoitika uye inokonzeresa kuwedzera kwevhoriyamu. Nekudaro, nekuda kwekuvharirwa kweiyo core iyo isati yave neshanduko, iyo yepamusoro layer inogadzira compression stress, nepo core ine tensile stress. Kana kushushikana kwakakura zvakakwana, kunokonzera deformation. Kana iyo musimboti yakatonhodzwa kusvika kuMs point, inozoitawo martensitic shanduko uye kuwedzera muhuwandu. Zvisinei, nekuda kwezvipingamupinyi zvekushandurwa kwepamusoro kwepamusoro nepurasitiki yakaderera uye simba rakakwirira, kushushikana kwayo kwekupedzisira kunenge kwasara kuchava muchimiro chekushungurudzika kwepamusoro, uye nheyo ichaita Pasi pekumanikidzwa. Zvinogona kuoneka kuti shanduko uye mamiriro ekupedzisira echikamu chekushandura kushushikana kwakanyatso kupesana nekushushikana kwekupisa. Uyezve, sezvo kushushikana kwechikamu kunoitika pakudziya kwakaderera nepurasitiki yakaderera, deformation yakaoma panguva ino, saka chikamu chekuchinja kushushikana kunonyanya kukonzera kutsemuka kweiyo workpiece.

Pane zvinhu zvakawanda zvinokanganisa ukuru hwechikamu chekushandura kushushikana. Iyo inokurumidza kukurumidza kutonhora kwesimbi mumartensite shanduko yetembiricha siyana, iyo yakakura saizi yesimbi chidimbu, yakaipisisa thermal conductivity yesimbi, iyo yakakura iyo chaiyo vhoriyamu yemartensite, iyo huru yechikamu shanduko kushushikana. Kukura kwazvinoita. Mukuwedzera, chikamu chekushandura kushungurudza kunobatanidzawo nekuumbwa kwesimbi uye kuoma kwesimbi. Semuenzaniso, yakakwira kabhoni yakakwira alloy simbi inowedzera chaiyo vhoriyamu yemartensite nekuda kweiyo yakakwira kabhoni yemukati, iyo inofanirwa kuwedzera chikamu chekushandura kushushikana kwesimbi. Nekudaro, sezvo iyo kabhoni yemukati inowedzera, iyo Ms point inodzikira, uye kune yakawanda yakachengetwa austenite mushure mekudzima. Kuwedzera kwehuwandu hwayo kunoderera uye kusara kwekunetseka kwakaderera.

(2) Deformation ye workpiece panguva yekudzima

Panguva yekudzima, kune maviri makuru emhando ye deformation mune workpiece: imwe ndiyo shanduko ye geometric chimiro che workpiece, iyo inoratidzwa sekuchinja kwehukuru uye chimiro, inowanzonzi warping deformation, iyo inokonzerwa nekudzima kushushikana; imwe yacho vhoriyamu deformation. , iyo inozviratidza sekuwedzera kwakaenzana kana kuderera kwehuwandu hwebasa rekushanda, rinokonzerwa nekushandurwa kwehuwandu hwehuwandu panguva yekuchinja kwechikamu.

Warping deformation inosanganisirawo chimiro deformation uye twisting deformation. Twist deformation inonyanya kukonzerwa nekuiswa kusina kunaka kwe workpiece muchoto panguva yekupisa, kana kushaya kuumbwa kwekugadzirisa mushure mekugadziriswa kwekugadzirisa kusati kwadzima, kana kutonhora kusina kuenzana kwezvikamu zvakasiyana-siyana zve workpiece apo workpiece inotonhora. Iyi deformation inogona kuongororwa uye kugadziriswa kune chaiwo mamiriro. Izvi zvinotevera zvinonyanya kukurukura vhoriyamu deformation uye chimiro deformation.

1) Zvikonzero zvekudzima deformation uye kuchinja kwayo mitemo

Volume deformation inokonzerwa nekushandurwa kwemaitiro Mamiriro ekugadzirisa workpiece asati adzima kazhinji pearlite, kureva, yakasanganiswa chimiro cheferrite uye cementite, uye mushure mekudzima iyo martensitic chimiro. Iwo akasiyana chaiwo mavhoriyamu ematishu aya anokonzeresa shanduko yevhoriyamu pamberi uye mushure mekudzima, zvichikonzera deformation. Nekudaro, iyi deformation inongokonzeresa kuti workpiece iwedzere uye chibvumirano chakaenzana, saka haichinje chimiro cheworkpiece.

Pamusoro pezvo, iyo yakawanda martensite muchimiro mushure mekupisa kupisa, kana iyo yakakwira iyo kabhoni yemukati mumartensite, iyo yakakura vhoriyamu yekuwedzera, uye yakakura huwandu hwakachengetwa austenite, iyo shoma vhoriyamu yekuwedzera. Naizvozvo, shanduko yevhoriyamu inogona kudzorwa nekudzora hukama hwemartensite uye yakasara martensite panguva yekupisa kurapwa. Kana ikadzorwa zvakanaka, vhoriyamu haizowedzeri kana kudzikira.

Shape deformation inokonzerwa nekushushikana kwekushisa Deformation inokonzerwa nekupisa kwekushisa kunoitika munzvimbo dzekushisa kwepamusoro apo simba regoho rezvikamu zvesimbi rakaderera, plastiki yakakwirira, nzvimbo inotonhora nokukurumidza, uye kusiyana kwekushisa pakati pemukati nekunze kwe workpiece ndiyo yakakura. Panguva ino, iyo pakarepo yekupisa kushushikana ndeye pamusoro tensile kusagadzikana uye musimboti compressive kusagadzikana. Sezvo tembiricha yepakati yakakwira panguva ino, simba regoho rakaderera zvakanyanya kupfuura pamusoro, saka rinoratidza sedeformation pasi pechiito che-multi-directional compressive stress, ndiko kuti, cube iri spherical munzira. Variety. Mhedzisiro yacho ndeyekuti hombe inodzikira, nepo diki ichiwedzera. Semuenzaniso, silinda refu inopfupika mukureba kutungamira uye inowedzera mudhayamita nzira.

Shape deformation inokonzerwa nekushushikana kwetishu Deformation inokonzerwa nekushushikana kwetishu kunoitikawo panguva yekutanga apo kushushikana kwetishu kwakanyanya. Panguva ino, mutsauko wemuchinjika-chikamu chetembiricha yakakura, tembiricha yepakati yakakwira, ichiri muaustenite state, iyo plasticity yakanaka, uye simba regoho rakaderera. Iko pakarepo kushushikana kwetishu ndeyekumanikidza kudzvinyirira uye core tensile stress. Naizvozvo, iyo deformation inoratidzwa sekurebesa kwepakati pasi pechiito che-multi-directional tensile stress. Mhedzisiro yacho ndeyokuti pasi pekuita kwekushushikana kwetishu, rutivi rukuru rwebasa rinorebesa, nepo rutivi ruduku runopfupika. Semuenzaniso, deformation inokonzerwa nekushushikana kwetishu muhumburumbira refu ndeyekureba uye kuderedzwa kwedhayamita.

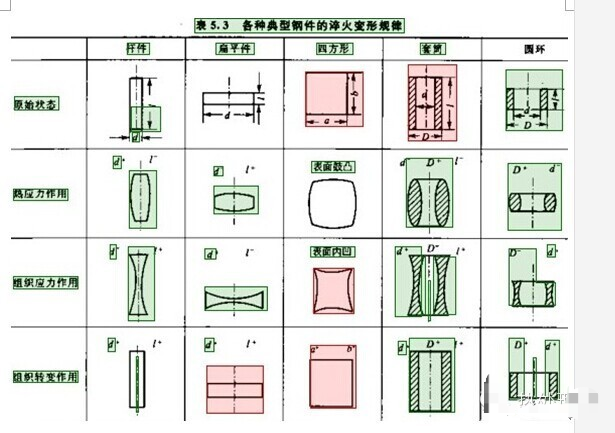

Tafura 5.3 inoratidza iyo yekudzima deformation mitemo yeakasiyana akajairwa simbi zvikamu.

2) Zvinhu zvinokanganisa kudzima deformation

Izvo zvinhu zvinokanganisa kudzima deformation zvinonyanya kuumbwa kwekemikari yesimbi, chimiro chepakutanga, geometry yezvikamu uye nzira yekurapa kupisa.

3) Kudzima mitswe

Kutsemuka muzvikamu zvinonyanya kuitika munguva yekupedzisira yekudzima uye kutonhora, ndiko kuti, mushure mekunge shanduko yemartensitic yapedzwa kana mushure mekutonhodzwa kwakazara, kukundikana kwebrittle kunoitika nekuti kushushikana kwekunetseka muzvikamu kunodarika simba rekutsemuka kwesimbi. Kutsemuka kunowanzo kutenderera kune kutungamira kweakanyanya tensile deformation, saka dzakasiyana siyana dzekutsemuka muzvikamu zvinonyanya kuenderana nekushushikana kwekugovera mamiriro.

Mhando dzakajairika dzekudzima kuputika: Longitudinal (axial) kuputika kunonyanya kugadzirwa apo tangential tensile stress inodarika simba rekupwanya rezvinyorwa; kutsemuka kwakachinjika kunoumbwa kana iyo hombe axial tensile stress inoumbwa mukati mechikamu chechikamu ichidarika simba rekupwanya rezvinhu. Cracks; network mitswe inoumbwa pasi pechiito che-two-dimensional tensile stress pamusoro pepamusoro; peeling mitswe inoitika mune yakaonda kwazvo yakaomeswa layer, iyo inogona kuitika kana kushushikana kwachinja zvakanyanya uye yakawandisa tensile stress inobata muradial direction. Mhando yekutsemuka.

Longitudinal cracks inonziwo axial cracks. Kutsemuka kunoitika pakunyanya kusimba kushushikana padhuze nepamusoro pechikamu, uye kuve nehumwe hudzamu hwakananga pakati. Iyo nzira yekutsemuka inowanzoenderana neaxis, asi iyo nzira inogona zvakare kushanduka kana paine kushushikana kusungirirwa muchikamu kana kana paine mukati mukati mehurema.

Mushure mokunge workpiece yadzimwa zvachose, kureba kwenguva refu kunowanzoitika. Izvi zvine chekuita neiyo yakakura tangential tensile kushushikana pamusoro peiyo yakadzimwa workpiece. Sezvo iyo kabhoni yesimbi yesimbi inowedzera, tsika yekugadzira longitudinal cracks inowedzera. Yakaderera kabhoni simbi ine diki chaiyo vhoriyamu yemartensite uye yakasimba yekupisa kushushikana. Pane yakakura yasara yekumanikidza kudzvinyirira pamusoro, saka hazvisi nyore kudzimwa. Sezvo iyo kabhoni yemukati ichiwedzera, iyo yepamusoro compressive kusagadzikana inodzikira uye kushushikana kwechimiro kunowedzera. Panguva imwecheteyo, iyo peak tensile stress inofamba ichienda kumusoro. Naizvozvo, yakakwira kabhoni simbi inowanzoita longitudinal quenching mitswe kana yanyanya kupisa.

Ukuru hwezvikamu zvinokanganisa zvakananga ukuru uye kugoverwa kwekunetseka kwakasara, uye maitiro ayo ekudzima kuputika kwakasiyanawo. Longitudinal cracks zvakare inoumbwa nyore nyore nekudzima mukati meiyo ine ngozi muchinjiko-chikamu saizi renji. Mukuwedzera, kuvhara kwesimbi mbishi zvinhu zvinowanzokonzera kureba kwenguva refu. Sezvo zvikamu zvakawanda zvesimbi zvinogadzirwa nekukunguruka, kwete-goridhe inclusions, carbides, nezvimwewo musimbi inogoverwa pamwe nedeformation direction, zvichiita kuti simbi ive anisotropic. Semuyenzaniso, kana turusi simbi ine bhendi-kufanana chimiro, kuchinjika kwayo kutsemuka simba pashure quenching iri 30% kusvika 50% diki pane longitudinal kutsemuka simba. Kana pane zvinhu zvakadai sezvisina-goridhe inclusions musimbi inokonzera kushungurudzika, kunyange kana tangential stress yakakura kudarika axial stress, Longitudinal cracks iri nyore kuumba pasi pemamiriro ezvinhu akaderera. Nokuda kwechikonzero ichi, kutonga kwakasimba kweyero ye-non-metallic inclusions uye shuga musimbi chinhu chakakosha mukudzivirira kudzima kuputika.

Iyo yemukati yekushushikana yekuparadzira maitiro eakachinjika makatsemuka uye arc makatsemuka ndeaya: iyo nzvimbo iri pasi pekumanikidza kudzvinyirira. Mushure mekubva pamusoro peimwe chinhambwe, iyo compression stress inoshanduka kuita yakakura tensile stress. Kutsemuka kunoitika munzvimbo yekushushikana kwekushushikana, uyezve kana kushushikana kwemukati Kunopararira kumusoro kwechikamu chete kana ikagovaniswazve kana brittleness yesimbi inowedzera kuwedzera.

Kutsemuka kwakachinjika kunowanzoitika muzvikamu zvakakura zveshaft, senge rollers, turbine rotors kana zvimwe zvikamu zve shaft. Hunhu hwekutsemuka ndehwekuti ivo vari perpendicular kune axis kutungamira uye kutyora kubva mukati kuenda kunze. Vanowanzoumbwa vasati vaomeswa uye zvinokonzerwa nekupisa kwekushisa. Makuru ekugadzira anowanzo aine metallurgical defects senge pores, inclusions, forging cracks uye mavara machena. Izvi zvinokanganisa zvinoshanda senzvimbo yekutanga yekutyoka uye kutyora pasi pechiito che axial tensile kusagadzikana. Kuputika kweArc kunokonzerwa nekupisa kwekushisa uye kunowanzogoverwa mu arc shape pane zvikamu apo chimiro chechikamu chinoshanduka. Iyo inonyanya kuitika mukati meworkpiece kana padyo nemicheto yakapinza, grooves nemakomba, uye inogoverwa mune arc chimiro. Kana zvikamu zvesimbi zvakakwirira-kabhoni zvine dhayamita kana ukobvu hwe80 kusvika 100 mm kana kudarika zvikasadzimwa, pamusoro pacho panoratidza kudzvanyirira kushushikana uye pakati pacho panoratidza kushushikana. Kushungurudzika, iyo yakanyanya kushushikana kushushikana inoitika munzvimbo yekuchinja kubva kune yakaomeswa layer kusvika kune isina-yakaomeswa layer, uye arc kuputika kunoitika munzvimbo idzi. Mukuwedzera, chiyero chekutonhora pamicheto yakapinza uye makona inokurumidza uye zvose zvinodzimwa. Kana uchichinjika kuenda kuzvikamu zvinyoro, ndiko kuti, kunzvimbo isina kuomeswa, iyo yakanyanya tensile stress zone inoonekwa pano, saka arc kutsemuka kunowanzoitika. Mwero wekutonhodza padhuze negomba repini, groove kana buri repakati pebasa rinononoka, iyo inopindirana yakaomeswa layer yakatetepa, uye kushushikana kwekumanikidza padhuze neakaomeswa shanduko zone kunogona kukonzera kutsemuka kwearc zviri nyore.

Kutsemuka kwereticular, kunozivikanwawo sekutsemuka kwepamusoro, kutsemuka kwepamusoro. Kudzika kwekutsemuka hakuna kudzika, kazhinji kutenderera 0.01 ~ 1.5mm. Hunhu hukuru hwerudzi urwu rwekutsemuka ndeyekuti kutungamira kwekutsemuka hakuna chekuita nechimiro chechikamu. Mitswe yakawanda yakabatana kune imwe neimwe kuita network uye inoparadzirwa zvakanyanya. Kana kudzika kwakadzika kwakakura, sekupfuura 1 mm, hunhu hwenetiweki hunonyangarika uye hunobva hwaenda zvisina tsarukano kana kugovaniswa kwenguva refu. Network cracks ine chekuita nechimiro chembiri-dimensional tensile stress pamusoro pepamusoro.

Yakakwira kabhoni kana carburized simbi zvikamu zvine decarburized layer pamusoro pepamusoro zvinowanzoita kuumba network kutsemuka panguva yekudzima. Izvi zvinodaro nekuti iyo yepamusoro layer ine yakaderera kabhoni yemukati uye idiki chaiyo vhoriyamu pane yemukati layer yemartensite. Munguva yekudzima, iyo yepamusoro ye carbide inoiswa pasi pekunetseka kwekunetseka. Zvikamu zvine dephosphorization layer isina kubviswa zvachose panguva yekugadziriswa kwemechini inozogadzirawo kutsemuka kwetiweki panguva yepamusoro-frequency kana murazvo wekudzima. Kuti udzivise kuputika kwakadaro, hutano hwepamusoro hwezvikamu hunofanira kunyatsodzorwa, uye oxidation welding inofanira kudzivirirwa panguva yekupisa kupisa. Uye zvakare, mushure mekufa kwekugadzira kunoshandiswa kweimwe nguva yenguva, kupisa kuneta kwakatsemuka kunoonekwa mumitsetse kana network mugomba uye kuputika mukukuya kwezvikamu zvakadzimwa zvese ndezvefomu iri.

Peeling makatsemuka anoitika munzvimbo yakatetepa kwazvo yepasi layer. Compressive stress inobata muaxial uye tangential directions, uye tensile stress inoitika muradial direction. Kutsemuka kwakafanana nechepamusoro pechikamu. Kusvuura kweiyo yakaomeswa layer mushure mekudzima kwepamusoro uye zvikamu zve carburizing zvatonhodzwa ndezvekutsemuka kwakadaro. Chiitiko chayo chinobatana nechimiro chisina kuenzana mumucheka wakaoma. Semuenzaniso, mushure mekunge alloy carburized simbi yatonhodzwa pane imwe kumhanya, chimiro chiri mu carburized layer ndechekuti: yekunze layer yeyakanyanya kunaka pearlite + carbide, uye sublayer iri martensite + residual Austenite, iyo yemukati layer yakanaka pearlite kana yakanyanya kunaka pearlite chimiro. Sezvo maumbirwo chaiwo evhoriyamu ye-sub-layer martensite ndiyo yakakura, mhedzisiro yekuwedzera kwevhoriyamu ndeyekuti compressive stress inobata pamusoro pedenga muaxial uye tangential nhungamiro, uye kushushikana kwekushushikana kunoitika muradial direction, uye kushushikana kushanduka kunoitika mukati, kuchinjika kune inomanikidza kushushikana mamiriro, uye peeling mitswe Inoitika munzvimbo dzakatetepa zvakanyanya uko kushushikana kushanduka. Kazhinji, makatsemuka anohwanda mukati akatarisana nepamusoro, uye mumatambudziko akaomarara anogona kukonzera kupeuka kwepamusoro. Kana chiyero chekutonhora chezvikamu zve carburized chikakwidziridzwa kana kuderedzwa, yunifomu martensite chimiro kana ultra-yakanaka pearlite chimiro chinogona kuwanikwa mu carburized layer, iyo inogona kudzivirira kuitika kwekutsemuka kwakadaro. Mukuwedzera, panguva ye-high-frequency kana murazvo wemoto unodzima, nzvimbo yacho inowanzopisa uye iyo inhomogeneity yehutano pamwe chete nekuoma kwakaoma kunogona kuumba nyore kuputika kwepamusoro kwakadaro.

Microcracks yakasiyana kubva kune mana ataurwa pamusoro apa kuti anokonzerwa ne microstress. Intergranular makatsemuka kuti kuoneka pashure quenching, overheating uye kugaya pamusoro-kabhoni mudziyo simbi kana carburized workpieces, uyewo makatsemuka kunokonzerwa kwete nenguva tempering yakadzimwa zvikamu, zvose chokuita kuvapo uye kwakatevera kuwedzera microcracks musimbi.

Microcracks inofanira kuongororwa pasi pe microscope. Zvinowanzoitika pamiganhu yezviyo zvekutanga austenite kana panosangana mashizha emartensite. Mamwe makatsemuka anopinda mukati memartensite sheets. Tsvagiridzo inoratidza kuti ma microcracks anowanikwa mune flaky twinned martensite. Chikonzero ndechekuti iyo flaky martensite inodhumhana neimwe kana ichikura nekumhanya kwakanyanya uye inogadzira yakanyanya kushushikana. Nekudaro, iyo twinned martensite pachayo ine brittle uye haigone kuburitsa Plastic deformation inozorodza kushushikana, nekudaro ichikonzera nyore microcracks. Iwo austenite zviyo zvakakasharara uye kukanganisa kune microcracks kunowedzera. Kuvapo kwe microcracks musimbi kuchanyanya kuderedza simba uye plastiki yezvikamu zvakadzimwa, zvichiita kuti kukuvara kwekutanga (kuputsika) kwezvikamu.

Kuti udzivise ma microcracks mune yakakwirira-kabhoni simbi zvikamu, matanho akadai seakadzika kudzima tembiricha yekudziya, kuwana yakanaka martensite chimiro, uye kuderedza kabhoni yemukati mumartensite inogona kugamuchirwa. Mukuwedzera, kushatisa nenguva mushure mekudzima inzira inobatsira yekuderedza kushushikana kwemukati. Miedzo yakaratidza kuti mushure mekudzikamisa kwakakwana pamusoro pe200 ° C, iyo carbides inonaya pakuputika ine mhedzisiro ye "welding" kuputika, izvo zvinogona kuderedza zvakanyanya njodzi dze microcracks.

Izvo zviri pamusoro apa nhaurirano yezvikonzero uye nzira dzekudzivirira dzekutsemuka zvichibva pamaitiro ekuparadzira mutswe. Mukugadzirwa chaiko, kugovaniswa kwekutsemuka kunosiyana nekuda kwezvinhu zvakaita semhando yesimbi, chimiro chechikamu, uye kupisa uye kutonhora kugadzira tekinoroji. Dzimwe nguva makatsemuka atovepo asati apisa kurapwa uye kuwedzera kuwedzera panguva yekudzima; dzimwe nguva marudzi akati wandei ekutsemuka anogona kuoneka muchikamu chimwe chete panguva imwe chete. Muchiitiko ichi, zvichibva pane morphological maitiro ekutsemuka, macroscopic kuongororwa kwepamusoro pekuputsika, metallographic kuongorora, uye kana zvichidikanwa, kuongororwa kwemakemikari uye dzimwe nzira dzinofanira kushandiswa kuita ongororo yakazara kubva pamhando yezvinhu, chimiro chesangano kune zvikonzero zvekushushikana kwekurapa kupisa kuti uwane mutswe. zvikonzero zvikuru uye wozoona matanho ekudzivirira anoshanda.

Kuputsika kuongororwa kwekutsemuka inzira yakakosha yekuongorora zvikonzero zvekutsemuka. Chero kutsemuka kune pekutangira kwekutsemuka. Kudzima kutsemuka kunowanzo kutanga kubva panosangana nzvimbo yekutsemuka kweradial.

Kana mavambo ekutsemuka aripo pamusoro pechikamu, zvinoreva kuti kutsemuka kunokonzerwa nekunyanya kushushikana kunetseka pamusoro. Kana pasina kukanganisa kwemaitiro akadai se inclusions pamusoro pepamusoro, asi kune kushushikana kwekugadzirisa zvinhu zvakadai semakisi akakomba ebanga, oxide scale, makona akapinza ezvikamu zvesimbi, kana zvikamu zvekuchinja kwemaitiro, kuputika kunogona kuitika.

Kana mabviro ekutsemuka ari mukati mechikamu, ane hukama nekuremara kwezvinhu kana kuwandisa kwemukati kwasara tensile kusagadzikana. Iyo yakatsemuka pamusoro peyakajairika quenching igrey uye yakanaka porcelain. Kana nzvimbo yakatyoka yakasviba grey uye yakaoma, inokonzerwa nekupisa kana kuti yepakutanga tishu yakakora.

Kazhinji kutaura, hapafanirwe kuve neruvara rweoxidation pachikamu chegirazi chekudzima mutswe, uye hapafanirwe kuve nedecarburization yakatenderedza mutswe. Kana paine decarburization kutenderedza mutswe kana oxidized ruvara pamusoro mutswe chikamu, zvinoratidza kuti chikamu nechekare makatsemuka asati quenching, uye chepakutanga makatsemuka achawedzera pasi pesimba kupisa kurapwa kunetseka. Kana zvakaparadzana carbides uye inclusions zvichionekwa pedyo nekutsemuka kwechikamu, zvinoreva kuti kuputika kwakabatana nekuparadzaniswa kwakanyanya kwecarbides mune zvakasvibiswa kana kuvapo kwekubatanidzwa. Kana makatsemuka achionekwa chete pamakona akapinza kana kuumba shanduko yezvikamu zvechikamu pasina chiitiko chiri pamusoro, zvinoreva kuti kutsemuka kunokonzerwa nekusanzwisisika kwemaitiro ekugadzira chikamu kana matanho asina kukodzera ekudzivirira kutsemuka, kana kupisa kwakanyanya kushushikana kwekurapa.

Pamusoro pezvo, kutsemuka kwemakemikari ekupisa kurapwa uye pamusoro pekudzima zvikamu zvinonyanya kuoneka padyo neyakaomeswa layer. Kuvandudza chimiro cheiyo yakaomeswa mbiru uye kuderedza kupisa kupisa kushushikana inzira dzakakosha dzekudzivirira kuputika kwepamusoro.

Nguva yekutumira: May-22-2024