1. Solder

Ese marudzi emasoja ane tembiricha yakaderera pane 3000 ℃ anogona kushandiswa W brazing, uye mhangura kana sirivheri based solders inogona kushandiswa kune zvikamu zvine tembiricha yakaderera pane 400 ℃;Ndarama yakavakirwa, manganese yakavakirwa, manganese yakavakirwa, palladium yakavakirwa kana drill based filler masimbi anowanzo shandiswa kune zvikamu zvinoshandiswa pakati pe400 ℃ ne900 ℃;Kune zvikamu zvinoshandiswa pamusoro pe1000 ℃, simbi dzakachena dzakadai seNb, Ta, Ni, Pt, PD uye Mo dzinonyanya kushandiswa.Kushanda tembiricha yezvikamu zvakashongedzwa neplatinamu base solder yasvika 2150 ℃.Kana 1080 ℃ diffusion kurapwa kunoitwa mushure mebrazing, yakanyanya tembiricha yekushanda inogona kusvika 3038 ℃.

Mazhinji emasoja anoshandiswa kubhura w anogona kushandiswa kubhuroka Mo, uye mhangura kana sirivha-based solders inogona kushandiswa kuMo components kushanda pasi pe400 ℃;Kune zvigadzirwa zvemagetsi uye zvisiri zvimiro zvikamu zvinoshanda pa400 ~ 650 ℃, Cu Ag, Au Ni, PD Ni kana Cu Ni vatengesi vanogona kushandiswa;Titanium yakavakirwa kana imwe yakachena simbi yekuzadza simbi ine yakakwira kunyungudika inogona kushandiswa kune zvikamu zvinoshanda pakupisa kwepamusoro.Izvo zvinofanirwa kucherechedzwa kuti manganese yakavakirwa, cobalt yakavakirwa uye nickel yakavakirwa mazadza masimbi kazhinji haakurudzirwe kudzivirira kuumbwa kwebrittle intermetallic komisheni mumajoini ekubhuroka.

Kana TA kana Nb zvikamu zvichishandiswa pazasi 1000 ℃, mhangura yakavakirwa, manganese yakavakirwa, cobalt yakavakirwa, titanium yakavakirwa, nickel yakavakirwa, goridhe yakavakirwa uye palladium majekiseni anogona kusarudzwa, kusanganisira Cu Au, Au Ni, PD Ni uye Pt Au_ Ni uye Cu Sn vatengesi vane yakanaka wettability kune TA neNb, yakanaka brazing seam kuumba uye yakakwirira majoini simba.Sezvo simbi yakavakirwa simbi yekuzadza simbi inowanzoita kuti simbi dzebrazing dziite brittle, dzinofanirwa kudzivirirwa zvakanyanya sezvinobvira.Kune zvikamu zvinoshandiswa pakati pe1000 ℃ uye 1300 ℃, simbi dzakachena Ti, V, Zr kana alloys zvichibva pane aya masimbi anoumba asingaperi akasimba uye mvura nawo anozosarudzwa sebrazing filler simbi.Kana tembiricha yebasa yakwira, simbi yekuzadza ine HF inogona kusarudzwa.

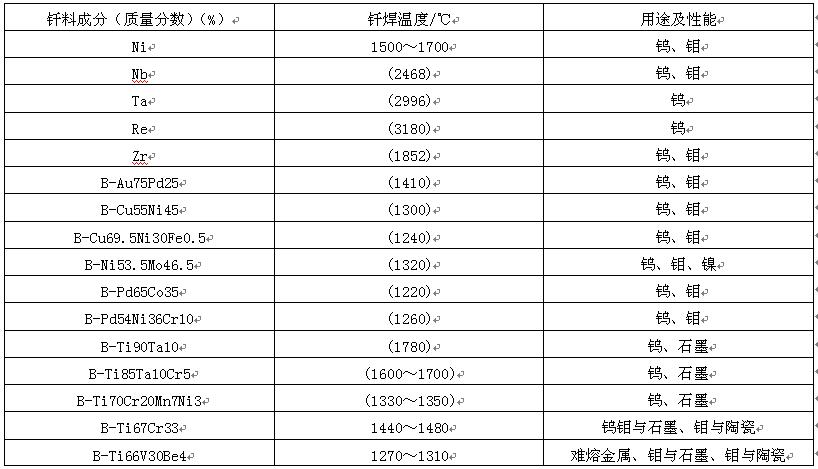

W. Ona tafura 13 yebrazing filler metals yeMo, Ta neNb pakupisa kwepamusoro.

Tafura 13 brazing filler simbi dzepamusoro tembiricha brazing yerefractory simbi

Usati waputira, zvinodikanwa kuti unyatsobvisa oxide pamusoro pesimbi inofuratira.Mechanical kugaya, jecha blasting, ultrasonic kuchenesa kana kuchenesa kemikari inogona kushandiswa.Brazing ichaitwa pakarepo mushure mekuchenesa.

Nekuda kweiyo yekuzvarwa brittleness yeW, w zvikamu zvinofanirwa kubatwa zvine hungwaru muchikamu chemusangano wekuita kuti usaputsika.Kuti udzivise kuumbwa kwebrittle tungsten carbide, kusangana kwakananga pakati peW uye graphite kunofanira kudziviswa.Kudzvanya nekuda kwe pre welding process kana welding inobviswa isati yaiswa welding.W iri nyore kuita oxidize kana tembiricha yakwira.Iyo vacuum degree ichave yakakwira zvakakwana panguva yekubhuroka.Kana kubhuroka kuchiitwa mukati mekupisa kwe1000 ~ 1400 ℃, iyo vacuum degree haizove isingasviki 8 × 10-3Pa. Kuti uvandudze tembiricha yekudzoreredza uye tembiricha yebasa rejoini, iyo brazing process inogona kusanganiswa ne The diffusion treatment after welding.Semuenzaniso, b-ni68cr20si10fel solder inoshandiswa braze W pa1180 ℃.Mushure mekurapa katatu kusanganisa kwe1070 ℃ / 4h, 1200 ℃ /3.5h uye 1300 ℃ / 2h mushure mekuputira, tembiricha yebasa rejoint brazed inogona kusvika kupfuura 2200 ℃.

Iyo diki coefficient yekuwedzera kwekupisa inofanirwa kuverengerwa pakuunganidza iyo brazed joint yeMo, uye gaka rekubatana rinofanira kunge riri mukati meiyo 0.05 ~ 0.13MM.Kana chigadziro chikashandiswa, sarudza chinhu chine coefficient chiduku chekuwedzera kwekushisa.Mo recrystallization inoitika kana murazvo wemoto unopisa, choto chemuchadenga chinodzorwa, choto chevacuum, firiji yekupinza uye kupisa kwekudzivirira kunodarika tembiricha yerecrystallization kana tembiricha yerecrystallization inodzikira nekuda kwekupararira kwezvinhu zvinotengeswa.Naizvozvo, kana tembiricha yebrazing iri padyo neiyo recrystallization tembiricha, iyo ipfupi nguva yekubhuroka, zviri nani.Kana uchibhuroka pamusoro petembiricha recrystallization yeMo, nguva yekubhuroka uye mwero wekutonhora unofanirwa kudzorwa kudzivirira kupaza kunokonzerwa nekunyanya kutonhora.Kana oxyacetylene flame brazing inoshandiswa, yakanakira kushandisa yakasanganiswa flux, kureva, maindasitiri borate kana sirivheri brazing flux pamwe nepamusoro-tembiricha flux ine calcium fluoride, inogona kuwana kuchengetedzwa kwakanaka.Iyo nzira ndeyekutanga kupfekedza dhizaini yesirivha brazing flux pamusoro peMo, uye wozopfekedza yakakwira-tembiricha flux.Sirivheri brazing flux ine chiitiko mune yakaderera tembiricha renji, uye inoshanda tembiricha yekumusoro-tembiricha inoyerera inogona kusvika 1427 ℃.

TA kana Nb zvikamu zvinonyanya kusungirirwa pasi pevacuum, uye iyo vacuum degree haisi pasi pe1.33 × 10-2Pa.Kana brazing ikaitwa pasi pekuchengetedzwa kwegasi inert, tsvina yegesi yakadai se carbon monoxide, ammonia, nitrogen uye carbon dioxide inofanira kubviswa zvakasimba.Kana brazing kana kuramba brazing ichiitwa mumhepo, yakakosha brazing filler simbi uye yakakodzera flux ichashandiswa.Kuti udzivise TA kana Nb kubva pakusangana neokisijeni pakupisa kwepamusoro, simbi yemhangura yendarira kana nickel inogona kuputirwa pamusoro uye inopindirana inopindirana annealing kurapwa inogona kuitwa.

Nguva yekutumira: Jun-13-2022