1. Kupisa zvinhu

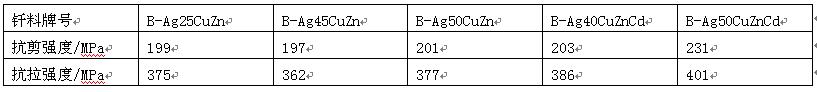

(1)Brazing yekabhoni simbi uye yakaderera alloy simbi inosanganisira yakapfava brazing uye yakaoma brazing.Solder inoshandiswa zvakanyanya mukunyorovesa solder itin lead solder.Kunyorova kweiyi solder kune simbi kunowedzera nekuwedzera kwetin content, saka solder ine tini yakakwirira inofanira kushandiswa kuvhara majoini.Fesn2 intermetallic compound layer inogona kuumbwa pane chinongedzo pakati petin nesimbi mune tin lead solder.Kuti udzivise kuumbwa kwekomboni mune iyi dhizaini, kupisa kwebrazing uye kubata nguva kunofanirwa kudzorwa zvakanaka.Simba rekugera remakabhoni simbi majoini akarukwa ane akati wandei akajairwa tin lead solders anoratidzwa muTafura 1. Pakati pawo, simba rekubatana rakashongedzwa ne50% w (SN) ndiro rakakwirira, uye simba rekubatana rakasungwa ne antimony free solder rakakwirira kudarika. kuti neantimoni.

Tafura 1 kusimba kwekugera kwekabhoni simbi majoini akarukwa nerata rinotungamira solder

Kana kubhuroka kabhoni simbi uye yakaderera alloy simbi, mhangura yakachena, zingi remhangura uye sirivheri mhangura zinc brazing filler simbi dzinonyanya kushandiswa.Mhangura yakachena ine yakakwira kunyungudika uye iri nyore kuisa oxidize base simbi panguva yekubhuroka.Inonyanya kushandiswa gasi yakadzivirirwa brazing uye vacuum brazing.Nekudaro, zvinofanirwa kucherechedzwa kuti gaka riri pakati pemajoini ebrazed rinofanira kunge riri pasi pe 0.05mm kuti udzivise dambudziko iro gaka rekubatana harigone kuzadzwa nekuda kwemvura yakanaka yemhangura.Iyo kabhoni simbi uye yakaderera alloy simbi majoini akashongedzwa nemhangura yakachena ane simba rakawanda.Kazhinji, simba rekugera i150 ~ 215mpa, nepo simba rekusimba richigoverwa pakati pe170 ~ 340mpa.

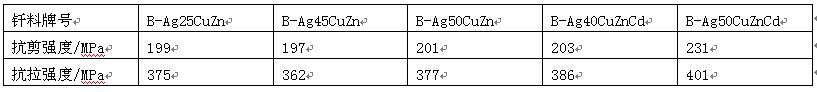

Kuenzaniswa nemhangura yakachena, nzvimbo yakanyunguduka yemhangura zinc solder inoderera nekuda kwekuwedzera kweZn.Kuti udzivise Zn evaporation panguva yekuputika, kune rumwe rutivi, zvishoma zveSi zvinogona kuwedzerwa kune mhangura zinc solder;Kune rimwe divi, nzira dzekudziya dzekukurumidza dzinofanirwa kushandiswa, senge murazvo wemoto, induction brazing uye dip brazing.Majoini ekabhoni simbi uye yakaderera alloy simbi yakashongedzwa nemhangura zinc filler simbi ine simba rakanaka uye plastiki.Semuyenzaniso, kusimba kwesimba uye kugera simba kwekabhoni simbi majoini akarukwa neb-cu62zn solder anosvika 420MPa uye 290mpa.Nzvimbo yakanyunguduka yesirivheri yemhangura chiteshi solder yakadzikira pane iya yemhangura zinc solder, iyo iri nyore kunyorera tsono.Iyi simbi yekuzadza inokodzera murazvo wemoto, induction brazing uye choto brazing yekabhoni simbi uye yakaderera alloy simbi, asi zvirimo muZn zvinofanirwa kuderedzwa zvakanyanya sezvinobvira panguva yekupisa kwechoto, uye chiyero chekupisa chinofanira kuwedzerwa.Brazing kabhoni simbi uye yakaderera alloy simbi ine sirivheri mhangura zinc filler simbi inogona kuwana majoini nesimba rakanaka uye plastiki.Iyo chaiyo data yakanyorwa muTafura 2.

Tafura 2 simba repasi kabhoni simbi majoini akarukwa nesirivha mhangura zinc solder

(2) Flux: flux kana kudzivirira gasi ichashandiswa kubhuroka kabhoni simbi uye yakaderera alloy simbi.Iyo flux inowanzo temwa neakasarudzwa filler simbi uye brazing nzira.Kana tin lead solder ikashandiswa, iyo yakasanganiswa mvura ye zinc chloride uye ammonium chloride inogona kushandiswa se flux kana imwe yakakosha flux.Iyo yakasara yeiyi flux inowanzo shatisa zvakanyanya, uye iyo joint inofanira kunyatsocheneswa mushure mekubhuroka.

Kana uchigaya nemhangura zinc filler simbi, fb301 kana fb302 flux ichasarudzwa, kureva, borax kana musanganiswa weborax neboric acid;Mukupisa kwemoto, musanganiswa wemethyl borate uye formic acid inogonawo kushandiswa sebrazing flux, umo B2O3 vapor inoita basa rekubvisa firimu.

Kana sirivha mhangura zinc brazing filler simbi inoshandiswa, fb102, fb103 uye fb104 brazing fluxes inogona kusarudzwa, kureva, musanganiswa weborax, boric acid uye mamwe fluorides.Iyo yakasara yeiyi flux inoodza kune imwe nhanho uye inofanirwa kubviswa mushure mekubhuroka.

2. Brazing teknolojia

Iyo yepamusoro ichave yakashongedzwa ichacheneswa nemichina kana makemikari nzira kuti ive nechokwadi chekuti oxide firimu uye organic zvinhu zvabviswa zvachose.Nzvimbo yakacheneswa haifanire kushata uye haifanire kunamatira kune simbi machipisi kana imwe tsvina.

Carbon simbi uye yakaderera alloy simbi inogona kuvezwa neyakasiyana nzira dzakajairwa dzekubhejera.Munguva yekupisa kwemurazvo, murazvo usina kwawakarerekera kana kuti unodzikisira zvishoma unofanirwa kushandiswa.Panguva yekushanda, kupisa kwakananga kwesimbi yekuzadza uye kuyerera nemurazvo kunofanirwa kudzivirirwa zvakanyanya sezvinobvira.Kurumidza kupisa nzira dzakadai se induction brazing uye dip brazing dzakanyatsokodzera kubhuroka kwesimbi yakadzimwa uye yakadzikama.Panguva imwecheteyo, kudzima kana kuputika pane tembiricha yakaderera pane kupisa kunofanirwa kusarudzwa kudzivirira kupfava kwesimbi yepasi.Kana uchigadzira yakaderera alloy yakakwira simba simbi mumhepo yekudzivirira, kwete chete kuchena kwegasi kunodiwa, asiwo gasi flux inofanirwa kushandiswa kuve nechokwadi chekunyorova uye kupararira kwesimbi yekuzadza pamusoro pesimbi yepasi.

Iyo yakasara flux inogona kubviswa nemakemikari kana mechanical nzira.Izvo zvakasara zve organic brazing flux zvinogona kupukuta kana kucheneswa nepeturu, doro, acetone uye mamwe organic solvents;Izvo zvakasara zvehurosi hwakasimba hwakadai se zinc chloride uye ammonium chloride inofanira kuderedzwa muNaOH aqueous solution kutanga, uye yozocheneswa nemvura inopisa uye inotonhora;Boric acid uye boric acid flux residues yakaoma kubvisa, uye inogona kugadziriswa chete nemichina yemagetsi kana kunyudzwa kwenguva refu mumvura inokwira.

Nguva yekutumira: Jun-13-2022