1. Brazeability

Iyo brazing pfuma yealuminium nealuminium alloys haina kunaka, kunyanya nekuti iyo oxide firimu iri pamusoro yakaoma kubvisa.Aluminium ine hukama hukuru hweokisijeni.Zviri nyore kuumba dense, yakagadzikana uye yakakwirira melting point oxide film Al2O3 pamusoro.Panguva imwecheteyo, aruminiyamu alloys ane magnesium anozogadzirawo yakagadzikana kwazvo oxide film MgO.Vachadzivirira zvakanyanya kunyorova uye kupararira kwe solder.Uye zvakaoma kubvisa.Munguva yebrazing, iyo brazing process inogona kuitwa chete neyakakodzera flux.

Chechipiri, kushanda kwealuminium uye aluminium alloy brazing kwakaoma.Iko kunyunguduka kwealuminium uye aluminium alloy haina kunyanya kusiyana neiyo yebrazing filler metal inoshandiswa.Iyo yesarudzo tembiricha yemhando yebrazing yakatetepa.Kudzora kushoma kwakashata kuri nyore kukonzeresa kupisa kana kunyange kunyungudika kwesimbi yepasi, zvichiita kuti kubhuroka kuome.Mamwe aruminiyamu alloys anosimbiswa nekupisa kurapwa anozokonzeresa kupfava zviitiko senge pamusoro pekuchembera kana annealing nekuda kwekudziya kwebrazing, izvo zvinoderedza zvimiro zve brazed majoini.Munguva yekupisa kwemurazvo, zvakaoma kutonga tembiricha nekuti ruvara rwealuminium alloy harushanduke panguva yekupisa, izvo zvinowedzerawo zvinodiwa kune iyo opareta yekushanda pamwero.

Zvakare, iyo corrosion resistance yealuminium uye aluminium alloy brazed joints inokanganiswa zviri nyore nefiller metals uye fluxes.Iyo electrode inogoneka yealuminium uye aruminiyamu alloy yakasiyana chaizvo neye solder, iyo inoderedza kushomeka kwekupokana kwejoint, kunyanya kune yakapfava solder joint.Uye zvakare, mazhinji emagetsi anoshandiswa mukugadzika kwealuminium uye aruminiyamu alloys ane corrosivity yakasimba.Kunyangwe kana vakacheneswa mushure mekubhuroka, pesvedzero ye fluxes pane corrosion resistance yemajoini haizobviswe zvachose.

2. Kupisa zvinhu

(1) Brazing yealuminium uye aruminiyamu alloys inzira isingawanzo shandiswa, nekuti kuumbwa uye electrode kugona kwebrazing filler simbi uye base simbi zvakasiyana kwazvo, izvo zviri nyore kukonzera electrochemical corrosion yejoinhi.Iyo yakapfava solder inonyanya kutora zinc based solder uye tin lead solder, iyo inogona kukamurwa kuita yakaderera tembiricha solder (150 ~ 260 ℃), yepakati tembiricha solder (260 ~ 370 ℃) uye yakanyanya tembiricha solder (370 ~ 430 ℃) zvinoenderana ne tembiricha range.Kana tin lead solder ikashandiswa uye mhangura kana nickel isati yaiswa paaruminiyamu pamusoro pebrazing, corrosion pajoint interface inogona kudziviswa, kuitira kuti ivandudze corrosion resistance yejoint.

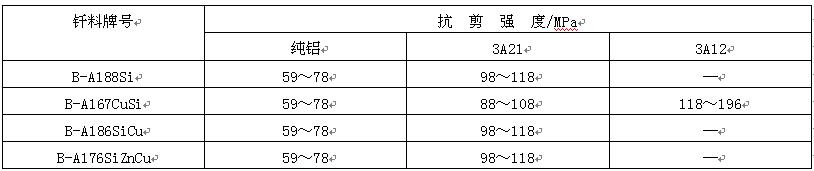

Brazing yealuminium uye aluminium alloys inoshandiswa zvakanyanya, senge sefa gidhi, evaporator, radiator uye zvimwe zvinhu.Chete aruminiyamu based filler masimbi anogona kushandiswa kubhuroka kwealuminium uye aluminium alloys, pakati peiyo aluminium silicon filler simbi ndiyo inonyanya kushandiswa.Iyo chaiyo chiyero chekushandisa uye simba rekugera remajoini akasungwa anoratidzwa muTafura 8 uye tafura 9 zvakateerana.Nekudaro, iyo inonyungudika yeiyi solder iri padyo neiyo yepasi simbi, saka tembiricha yekudziya inofanira kunyatsodzorwa uye yakanyatso kudzorwa panguva yebrazing kudzivirira kupisa kana kunyungudika kwesimbi yepasi.

Tafura 8 yekushandisa chiyero chebrazing filler masimbi ealuminium uye aluminium alloys

Tafura 9 yekugera simba realuminium uye aluminium alloy majoini akashongedzwa nealuminium silicon filler simbi.

Aluminium silicon solder inowanzo kupihwa muchimiro chehupfu, paste, waya kana sheet.Mune zvimwe zviitiko, solder composite mahwendefa ane aruminiyamu semusimboti uye aruminiyamu silicon solder sezvo cladding inoshandiswa.Iri rudzi rwe solder composite plate inogadzirwa ne hydraulic nzira uye inowanzoshandiswa sechikamu chebrazing components.Munguva yebrazing, iyo brazing filler simbi pane inoumbwa ndiro inonyungudika uye inoyerera pasi pechiito checapillary uye giravhiti yekuzadza gap rekubatana.

(2) Flux uye inodzivirira gasi yealuminium uye aluminium alloy brazing, yakakosha flux inowanzoshandiswa kubvisa iyo firimu.Iyo organic flux yakavakirwa pa triethanolamine, senge fs204, inoshandiswa ine yakaderera-tembiricha yakapfava solder.Kubatsira kweiyo flux ndeyokuti ine zvishoma corrosion effect pachigadziko chesimbi, asi inobudisa huwandu hwakawanda hwegesi, iyo inokanganisa wetting uye caulking ye solder.Iyo reactive flux yakavakirwa pazinc chloride, senge fs203 uye fs220a, inoshandiswa nepakati tembiricha uye tembiricha yakapfava solder.Iyo reactive flux inoparadza zvakanyanya, uye yakasara inofanira kubviswa mushure mekubhuroka.

Parizvino, kubhuroka kwealuminium uye aluminium alloys kuchiri kudzorwa nekubviswa kwemafirimu ekuyerera.Iyo brazing flux inoshandiswa inosanganisira chloride based flux uye fluoride based flux.Chloride based flux ine simba rakasimba rekubvisa oxide firimu uye yakanaka fluidity, asi ine yakakura corrosive mhedzisiro pane base simbi.Zvakasara zvaro zvinofanira kubviswa zvachose mushure mekugadzirisa.Fluoride based flux imhando nyowani yekuyerera, ine yakanaka yekubvisa firimu maitiro uye isina ngura kune base simbi.Nekudaro, ine yakakwira kunyungudika uye kushomeka kwekushisa, uye inogona kushandiswa chete nealuminium silicon solder.

Kana uchigadzira aluminium uye aluminium alloys, vacuum, neutral kana inert atmosphere inowanzoshandiswa.Kana vacuum brazing inoshandiswa, iyo vacuum dhigirii inowanzosvika pakurongeka kwe10-3pa.Kana nitrogen kana argon gasi ichishandiswa kudzivirira, kuchena kwayo kunofanira kunge kwakakwira zvakanyanya, uye dova rinofanira kunge rakaderera pane -40 ℃.

3. Brazing teknolojia

Brazing yealuminium uye aruminiyamu alloys ine zvakakwirira zvinodiwa pakuchenesa kweworkpiece pamusoro.Kuti uwane hutano hwakanaka, tsvina yemafuta uye oxide firimu pamusoro inofanira kubviswa isati yanyungudutswa.Bvisa tsvina yemafuta pamusoro neNa2CO3 aqueous solution pane tembiricha ye60 ~ 70 ℃ ye5 ~ 10min, wozogeza nemvura yakachena;Iyo yepamusoro oxide firimu inogona kubviswa ne etching neNaOH aqueous solution pane tembiricha ye20 ~ 40 ℃ ye2 ~ 4min, uye yozoshambidzwa nemvura inopisa;Mushure mokubvisa tsvina yemafuta uye oxide firimu pamusoro, workpiece ichabatwa neHNO3 aqueous solution ye gloss ye 2 ~ 5min, yozocheneswa mumvura inoyerera uye pakupedzisira yakaomeswa.Iyo workpiece inobatwa nenzira idzi haifanirwe kubatwa kana kusvibiswa neimwe tsvina, uye ichakwizwa mukati me6 ~ 8h.Zviri nani kubhuroka pakarepo kana zvichibvira.

Iyo nzira dzekubhuroka dzealuminium uye aluminium alloys dzinonyanya kusanganisira murazvo wemoto, solder iron brazing uye kuvheneka kwevira.Idzi nzira dzinowanzo shandisa flux mubrazing, uye dzine zvinodiwa zvakasimba pakupisa tembiricha uye nguva yekubata.Munguva yemoto wekubhejera uye simbi yekusimbisa, dzivirira kudziyisa iyo inoyerera yakananga nekupisa sosi kudzivirira iyo flux kubva pakupisa nekutadza.Sezvo aruminiyamu inogona kunyungudutswa mune yakapfava solder ine yakakwira zinc content, kupisa kunofanirwa kumiswa kana chibatanidza chaumbwa kudzivirira base metal corrosion.Mune zvimwe zviitiko, kubhuroka kwealuminium uye aluminium alloys dzimwe nguva hakushandisi flux, asi inoshandisa ultrasonic kana scraping nzira kubvisa firimu.Paunenge uchishandisa kukwesha kubvisa iyo firimu yekubhuroka, tanga kupisa iyo workpiece kusvika kune inodziya tembiricha, wobva wakwenya chikamu chebrazing chebasa racho nemagumo emudonzvo we solder (kana scraping tool).Paunenge uchipwanya iyo yepamusoro oxide firimu, iyo inopera solder ichanyunguduka nekunyorovesa base simbi.

Nzira dzeBrazing dzealuminium uye aruminiyamu alloys dzinonyanya kusanganisira kupisa kwemoto, kupisa kwechoto, dip brazing, vacuum brazing uye gasi rakadzivirirwa brazing.Flame brazing inonyanya kushandiswa kune zvidiki zvekushanda uye chidimbu chimwe chete kugadzira.Kuti udzivise kukundikana kwekuyerera nekuda kwekubatana pakati pezvisina kuchena muacetylene uye kuyerera kana uchishandisa oxyacetylene murazvo, zvakakodzera kushandisa peturu yakadzvanywa mhepo murazvo nekuderera kushoma kudzivirira oxidation yesimbi yepasi.Panguva yekushongedza chaiyo, iyo brazing flux uye filler simbi inogona kuiswa panzvimbo yakashongedzwa pachine nguva uye inopisa panguva imwe chete neworkpiece;Iyo workpiece inogona zvakare kupiswa kune yekudziya tembiricha kutanga, uye ipapo solder yakanyikwa ne flux inogona kutumirwa kunzvimbo yekubhuroka;Mushure mekunge iyo flux uye simbi yekuzadza yanyungudutswa, murazvo wekupisa unobviswa zvishoma nezvishoma mushure mekunge simbi yekuzadza yazadzwa zvakaenzana.

Kana uchigadzira aluminium uye aruminiyamu alloy muvira remhepo, iyo brazing filler simbi ichagadzikiswa, uye brazing flux ichanyungudutswa mumvura yakanyungudutswa kugadzirira mhinduro yakakora ine 50% ~ 75%, yobva yaputirwa kana kupfapfaidza. nzvimbo yebrazing.Huwandu hwakakodzera hwehupfu hwehupfu hunogona zvakare kuvharwa pane brazing filler simbi uye brazing pamusoro, uye ipapo yakaunganidzwa weldment ichaiswa muchoto chekudziya kupisa.Kuti udzivise chigadziko chesimbi kubva pakupisa kana kunyange kunyunguduka, kupisa kwekushisa kunofanira kunyatsodzorwa.

Paste kana foil solder inowanzo shandiswa kudip brazing yealuminium nealuminium alloys.Iyo yakaunganidzwa workpiece inofanira kupiswa isati yabikwa kuti iite tembiricha yayo padhuze netembiricha yebrazing, yobva yanyudzwa mubrazing flux yebrazing.Munguva yebrazing, tembiricha yebrazing uye nguva yebrazing ichadzorwa zvakanyanya.Kana kutonhora kwakanyanyisa, nheyo yesimbi iri nyore kunyunguduka uye solder iri nyore kurasika;Kana kutonhora kwakanyanya kuderera, solder haina kunyungudutswa zvakakwana, uye chiyero chebrazing chinoderera.Iyo tembiricha yebrazing ichatemwa zvichienderana nerudzi uye saizi yesimbi yepasi, kuumbwa uye kunyungudika kwesimbi yekuzadza, uye kazhinji iri pakati peiyo liquidus tembiricha yesimbi yekuzadza uye solidus tembiricha yesimbi yepasi.Nguva yekunyura yeworkpiece mubhati yekuyerera inofanirwa kuve nechokwadi chekuti solder inogona kunyungudika zvizere uye kuyerera, uye nguva yekutsigira haifanirwe kunge yakareba.Zvikasadaro, iyo silicon element mune solder inogona kupararira mu base simbi, ichiita base simbi padhuze nemusono brittle.

Mune vacuum brazing yealuminium uye aruminiyamu alloys, simbi inoshanda activator inowanzoshandiswa kugadzirisa pamusoro peoxyde firimu realuminium uye kuve nechokwadi chekunyorova uye kupararira kwe solder.Magnesium inogona kushandiswa zvakananga pane workpiece muchimiro chezvimedu, kana kuunzwa munzvimbo yebrazing muchimiro cheutsi, kana magnesium inogona kuwedzerwa kune aluminium silicon solder sechinhu chealloy.Kune iyo workpiece ine yakaoma dhizaini, kuitira kuti ive nechokwadi chakazara mhedzisiro ye magnesium vapor pachigadziko chesimbi uye nekuvandudza iyo brazing mhando, yemuno shielding process matanho anowanzo kutorwa, ndiko kuti, workpiece inotanga kuiswa mubhokisi resimbi isina tsvina (kazhinji. inozivikanwa sebhokisi rekuita), uye wozoiswa muvira rekutsvaira rekupisa kupisa.Vacuum Brazed Aluminium uye aruminiyamu alloy majoini ane yakatsetseka pamusoro uye dense brazed majoini, uye haidi kucheneswa mushure mekubhuroka;Nekudaro, iyo vacuum brazing mudziyo inodhura, uye iyo magnesium mhute inosvibisa choto zvakanyanya, saka inoda kucheneswa nekuchengetwa nguva nenguva.

Kana uchigadzira aluminium uye aluminium alloys mune kwaakarerekera kana inert mhepo, magnesium activator kana flux inogona kushandiswa kubvisa iyo firimu.Kana magnesium activator inoshandiswa kubvisa iyo firimu, huwandu hwemagesium hunodiwa hwakadzikira kupfuura yevacuum brazing.Kazhinji, w (mg) inenge 0.2% ~ 0.5%.Apo zvinyorwa zve magnesium zvakakwirira, hutano hwekubatana huchaderedzwa.NOCOLOK brazing nzira uchishandisa fluoride flux uye nitrogen kuchengetedza inzira nyowani yakagadziridzwa nekukurumidza mumakore achangopfuura.Sezvo iyo yakasara yefluoride flux isingatore unyoro uye isingaparadzi kune aluminium, maitiro ekubvisa flux zvakasara mushure mekubhuroka anogona kusiiwa.Pasi pekuchengetedzwa kwenitrogen, ishoma chete fluoride flux inoda kuvezwa, iyo simbi yekuzadza inogona kunyatsonyorovesa base simbi, uye zviri nyore kuwana emhando yepamusoro majoini.Parizvino, iyi NOCOLOK brazing nzira yakashandiswa mukugadzirwa kwakawanda kwealuminium radiator nezvimwe zvinhu.

Kune aruminiyamu nearuminiyamu alloy yakashongedzwa nekuyerera kunze kwefluoride flux, iyo inoyerera inosara inofanirwa kubviswa zvachose mushure mekubhuroka.Iyo yakasara ye organic brazing flux yealuminium inogona kugezwa ne organic mhinduro senge methanol uye trichlorethylene, isina neutralized ne sodium hydroxide aqueous solution, uye pakupedzisira kucheneswa nemvura inopisa uye inotonhora.Chloride ndiyo yakasara yebrazing flux yealuminium, inogona kubviswa maererano nenzira dzinotevera;Kutanga, nyura mumvura inopisa pa 60 ~ 80 ℃ ye10min, nyatsochenesa zvakasara pajojo rakashongedzwa nebhurashi, uye uchenese nemvura inotonhora;Wonyika mu15% nitric acid aqueous solution for 30min, wozoigeza nemvura inotonhora.

Nguva yekutumira: Jun-13-2022