1. Kupisa zvinhu

(1) Titanium nema base alloys ayo haawanzo simbiwa nesolder yakapfava.Iyo brazing filler simbi dzinoshandiswa kubhuroka dzinonyanya kusanganisira sirivheri base, aluminium base, titanium base kana titanium zirconium base.

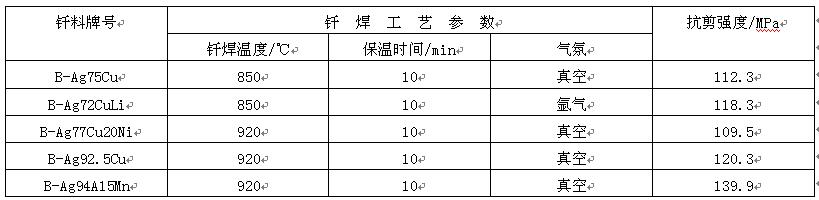

Silver based solder inonyanya kushandiswa kune zvikamu zvine tembiricha yekushanda isingasviki 540 ℃.Majoini anoshandisa yakachena sirivha solder ane simba rakaderera, nyore kutsemuka, uye kushomeka kwekuora uye kushongedzwa kweoxidation.Iyo tembiricha yekudziya yeAg Cu solder yakadzikira pane iyo sirivheri, asi kunyorova kunodzikira nekuwedzera kweCu content.Iyo Ag Cu solder ine hushoma hweLi inogona kuvandudza kunyorova uye iyo alloying degree pakati peiyo solder nesimbi yepasi.AG Li solder ine hunhu hwekuderera kunyungudika uye kusimba kwakasimba.Inokodzera brazing titanium uye titanium alloys mumhepo inodzivirira.Nekudaro, vacuum brazing ichasvibisa choto nekuda kweLi evaporation.Ag-5al- (0.5 ~ 1.0) Mn filler simbi ndiyo yakasarudzika simbi yekuzadza kune yakatetepa-yakavakirwa titanium alloy zvikamu.Iyo brazed joint ine yakanaka oxidation uye corrosion resistance.Simba rekugera retitanium uye titanium alloy majoini akashongedzwa nesirivha base yekuzadza simbi inoratidzwa muTafura 12.

Tafura 12 brazing process parameters uye kubatana kwesimba retitanium uye titanium alloys

Kupisa kwekupisa kwealuminium based solder kwakaderera, izvo zvisingazokonzerese kuitika kwetitanium alloy β Phase shanduko inoderedza zvinodiwa pakusarudzwa kwebrazing fixture materials uye zvimiro.Kudyidzana pakati pesimbi yekuzadza nesimbi yepasi kwakadzikira, uye kunyungudika uye kupararira hazvisi pachena, asi plastiki yesimbi yekuzadza yakanaka, uye zviri nyore kukungurutsa simbi yekuzadza nesimbi yepasi pamwechete, saka zviri nyore. yakanyatsokodzera brazing titanium alloy radiator, huchi chimiro uye laminate chimiro.

Titanium yakavakirwa kana titanium zirconium yakavakirwa fluxes kazhinji ine Cu, Ni uye zvimwe zvinhu, izvo zvinogona kukurumidza kupararira mumatrix uye kuita netitanium panguva yekubhuroka, zvichikonzera kuparara kwematrix uye kuumbwa kwebrittle layer.Naizvozvo, tembiricha yekudziya uye nguva yekubata inofanirwa kudzorwa zvakanyanya panguva yekubhuroka, uye haifanirwe kushandiswa kubhuroka kwezvivakwa zvakatetepa-madziro sezvinobvira.B-ti48zr48be yakajairika Ti Zr solder.Iyo ine yakanaka wettability kune titanium, uye simbi yepasi haina tsika yekukura kwezviyo panguva yekubhuroka.

(2) Brazing filler metals ye zirconium uye base alloys brazing ye zirconium uye base alloys anonyanya kusanganisira b-zr50ag50, b-zr76sn24, b-zr95be5, nezvimwewo, ayo anoshandiswa zvakanyanya mukubhuroka kwe zirconium alloy mapaipi emagetsi enyukireya reactor.

(3) Iyo brazing flux uye inodzivirira mamiriro titanium, zirconium uye base alloys anogona kuwana zvinogutsa mhedzisiro muvacuum uye inert mhepo (helium uye argon).High kuchena argon ichashandiswa kune argon shielded brazing, uye dova rinofanira kuva -54 ℃ kana pasi.Yakakosha flux ine fluoride uye chloride yesimbi Na, K uye Li inofanirwa kushandiswa mukupisa kwemoto.

2. Brazing teknolojia

Usati wapisa, nzvimbo yacho inofanira kunyatsocheneswa, yakasvibiswa uye firimu reoxide rinobviswa.Firimu reoxyde yakakora richabviswa nemuchina, nzira yekuputitsa jecha kana nzira yekugezesa yemunyu yakanyungudutswa.Iyo yakaonda oxide firimu inogona kubviswa mumhinduro ine 20% ~ 40% nitric acid uye 2% hydrofluoric acid.

Ti, Zr uye alloys avo haabvumidzwe kubata iyo yakabatana pamusoro nemhepo panguva yekupisa kupisa.Brazing inogona kuitwa pasi pekuchengetedzwa kwevacuum kana inert gasi.High frequency induction heat kana kupisa mukudzivirira inogona kushandiswa.Induction kupisa ndiyo nzira yakanakisa yezvikamu zvidiki zvakaenzanirana, nepo kubhuroka muchoto kunobatsira zvakanyanya kune zvakakura uye zvakaoma zvikamu.

Ni Cr, W, Mo, Ta uye zvimwe zvinhu zvichasarudzwa sezvinhu zvekupisa zvekushongedza Ti, Zr uye alloys avo.Zvishandiso zvine girafu yakafumurwa sezvinhu zvinodziya hazvishandiswe kudzivirira kusvibiswa kwekabhoni.Brazing inogadziriswa ichagadzirwa nemidziyo ine yakanaka-yepamusoro-tembiricha simba, yakafanana thermal yekuwedzera coefficient kuTi kana Zr, uye yakaderera reactivity ine base simbi.

Nguva yekutumira: Jun-13-2022